Soldering a Dome to a Backplate

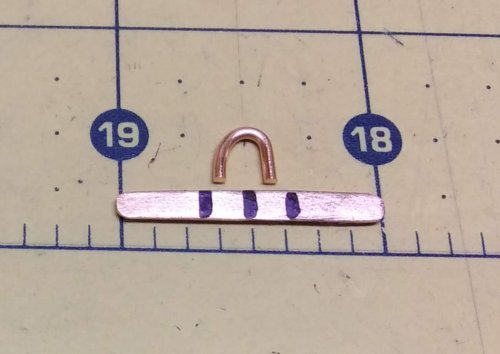

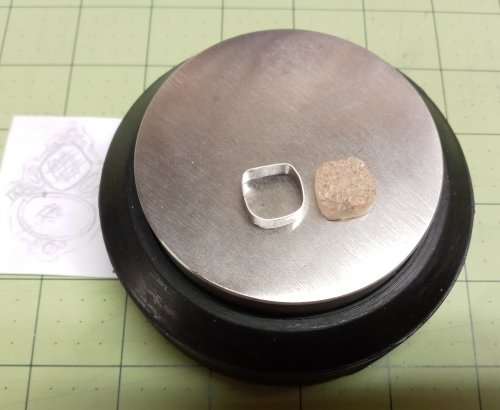

During the process of making a pair of silver and gold earrings inspired by organic Israeli designs, I needed to solder a hammered gold dome to a flat sheet of silver.

For safety, there must be a way for the air under the dome to escape. If both pieces fit flush together, the rapidly expanding heated air under the dome could cause the domed disc to pop off at a high velocity. It could strike you or those around you causing burns, hit something and break it, or land on a highly flammable surface and heaven forbid, start a fire.

Note: Whatever method used to solder two pieces together where there would be air that needs to escape, for your protection at the very least wear non-flammable clothing and face and eye protection. Better safe than sorry!

The easiest way to make sure the air can escape is to drill or punch a small hole in the back plate, or in an inconspicuous place on the domed disc.

For these earrings, since I challenged myself to make them a "design as you go" project with leftover materials from other projects, I decided against that. You may want to try one of these two options.

For safety, there must be a way for the air under the dome to escape. If both pieces fit flush together, the rapidly expanding heated air under the dome could cause the domed disc to pop off at a high velocity. It could strike you or those around you causing burns, hit something and break it, or land on a highly flammable surface and heaven forbid, start a fire.

Note: Whatever method used to solder two pieces together where there would be air that needs to escape, for your protection at the very least wear non-flammable clothing and face and eye protection. Better safe than sorry!

The easiest way to make sure the air can escape is to drill or punch a small hole in the back plate, or in an inconspicuous place on the domed disc.

For these earrings, since I challenged myself to make them a "design as you go" project with leftover materials from other projects, I decided against that. You may want to try one of these two options.

Instructions

Option 1: Heavily Textured Dome and Smooth Backplate: The uneven lower edge of the dome provides an avenue for the air to escape.

Heavily hammered discs often have uneven edges. After doming them, lightly sand a few spots on the bottom edge don't sand all the way around.

Leaving some areas unsanded allows air to escape during use. If you're still concerned about air flow, use a round file to remove a small section of metal in one spot on the dome's bottom edge.

Leaving some areas unsanded allows air to escape during use. If you're still concerned about air flow, use a round file to remove a small section of metal in one spot on the dome's bottom edge.

Place small amounts of paste solder around the inside bottom edge of each dome. Use about half the amount shown on the lower dome in the photo, applying it only to the flat, sanded areas inside the dome.

This prevents solder from filling gaps that allow air to escape.

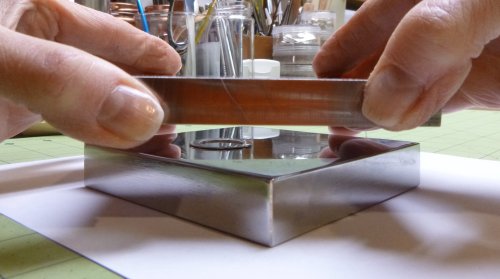

Set the piece on a flattened back and heat until the solder flows.

This prevents solder from filling gaps that allow air to escape.

Set the piece on a flattened back and heat until the solder flows.

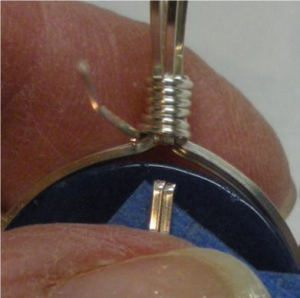

The lower edge of the hammered dome is visibly uneven. It was hidden with the coiled silver rings soldered around the edge.

Option 2: Smooth Dome and Heavily Textured Backplate: The low areas on the surface of the backplate provide an avenue for air to escape.

Sand the bottom edge of the dome flat.

As in the photo in Step 2, here way too much solder was placed inside the lower edge of the dome.

Use half that, and leave one area with no solder at all. Heat until the solder flows.

Use half that, and leave one area with no solder at all. Heat until the solder flows.

Because the bottom edge of the domed disc was sanded flat, it visibly looks like it is soldered fully around to the backing, even though it is not.

There is no need to hide the edge of the dome.

There is no need to hide the edge of the dome.

Materials

22 Gauge Dead Soft Argentium Silver Sheet - 6 Inches

H19-22SM6

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1 Inch

- Price: $104.76

- Gold Club Price: $78.57

WET/DRY PAPER 9 X 11 ASST- 20PC- 2EA GRIT 180-3000

ABR-500.90

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

Sterling Silver Wire in a variety of gauges

Tools

Basic Soldering Kit

G15-4

- G15-4

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $58.95

- Gold Club Price: $44.21

Blazer Big Buddy Turbo Torch, White

TRCH-8012

- TRCH-8012

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $40.00

- Gold Club Price: $30.00

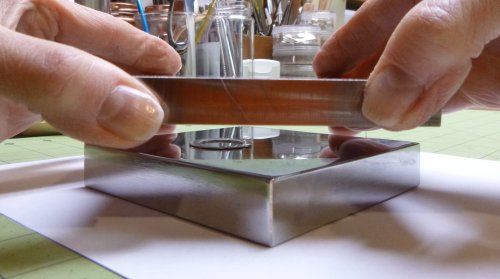

Bench Blocks - 130 X 130 X 20

DUR-1187

- DUR-1187

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $66.67

- Gold Club Price: $50.00

1 1/2 Inch Steel Dapping Block

G17-3

- G17-3

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.57

- Gold Club Price: $12.43

12 Piece Dapping Punch Set 3.6mm to 14mm

G17-4

- G17-4

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $12.97

- Gold Club Price: $9.73

6PC File Set

FIL-912.10

- FIL-912.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $39.97

- Gold Club Price: $29.98

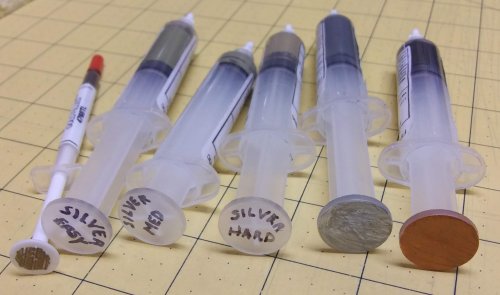

Silver Solder Paste Medium SS70 - 1/4 T.O.

SOL-822.15

- SOL-822.15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

Wubbers Artisan's Mark 4 Pc Texture Hammer Set

HAM-6100

- HAM-6100

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $99.95

- Gold Club Price: $74.96

12x12 Inch Rubber Mat

MAT-500.00

- MAT-500.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

- Category: Metalwork

- Technique(s): Butane Torch Techniques

Cleaning Your Jewelry

Cleaning Your Jewelry

Build A Tool Rack

Build A Tool Rack

Clamps for Jewelry Making

Clamps for Jewelry Making

Finishing Wire Ends

Finishing Wire Ends

Handmade Closures

Handmade Closures

Removing Tarnish From Your Jewelry

Removing Tarnish From Your Jewelry

Homemade Pickle

Homemade Pickle

Wire Wrapped Loops

Wire Wrapped Loops

How to Make Balled Head Pins

How to Make Balled Head Pins

Lessen the Noise - Save Your Eardrums

Lessen the Noise - Save Your Eardrums

Make a Rivet and Eyelet Tile

Make a Rivet and Eyelet Tile

Two Tips for Making Pendant Bails with Craft Wire

Two Tips for Making Pendant Bails with Craft Wire

Petal Forming on a Wood Block

Petal Forming on a Wood Block

Save Your Fingers while Texturing

Save Your Fingers while Texturing

Soldering on Copper

Soldering on Copper

Sticker Templates

Sticker Templates

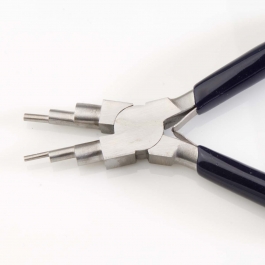

Using 6 Step Barrel Pliers

Using 6 Step Barrel Pliers

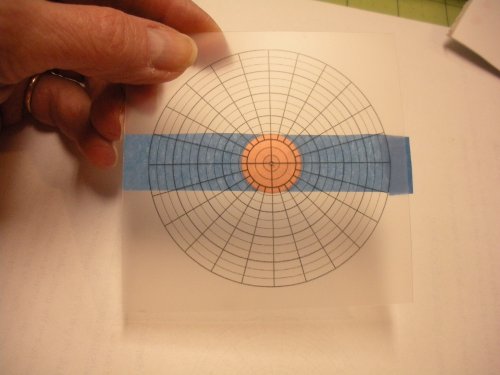

Using a Center Finder

Using a Center Finder

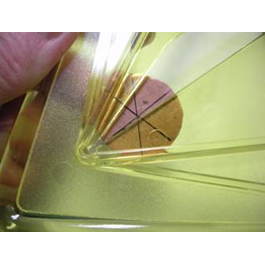

Using a Tile to Cut Rivets

Using a Tile to Cut Rivets

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Tiles on Tube Rivets and Eyelets

Using Tiles on Tube Rivets and Eyelets

Clothespin Tools

Clothespin Tools

Making Decorative Granulation Beads

Making Decorative Granulation Beads

Using Your Hole Punch Pliers

Using Your Hole Punch Pliers

Decorative Granulation and Beads

Decorative Granulation and Beads

How to Find and Mark the Center of a Disc.

How to Find and Mark the Center of a Disc.

Choosing the Right Clasp

Choosing the Right Clasp

Chunky Chain Inspiration

Chunky Chain Inspiration

Tool Tip - Steampunk or Industrial Rivets

Tool Tip - Steampunk or Industrial Rivets

Storing Jump Rings

Storing Jump Rings

Wear Your Brooches on a Neckwire

Wear Your Brooches on a Neckwire

Storing Your Metal

Storing Your Metal

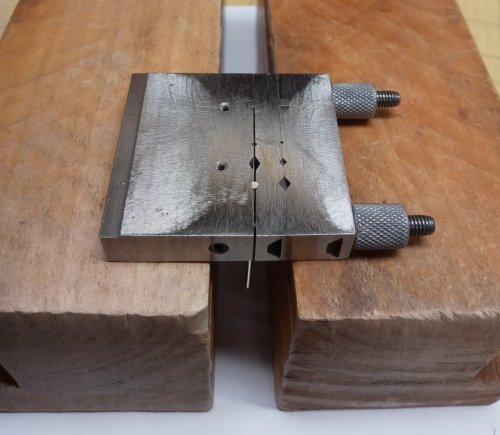

Using Disc Cutter Shims

Using Disc Cutter Shims

Conditioning a Rawhide Mallet

Conditioning a Rawhide Mallet

Flattening Metal Pieces

Flattening Metal Pieces

Quenching

Quenching

Saving a Broken Solder Brick

Saving a Broken Solder Brick

Why I Use Solder Paste

Why I Use Solder Paste

Designing a Toggle Clasp That Works

Designing a Toggle Clasp That Works

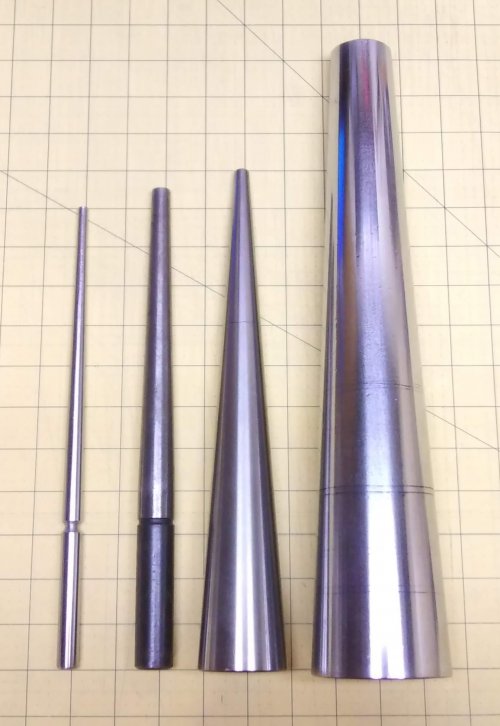

Round Mandrels

Round Mandrels

Get the Look of Eyelets

Get the Look of Eyelets

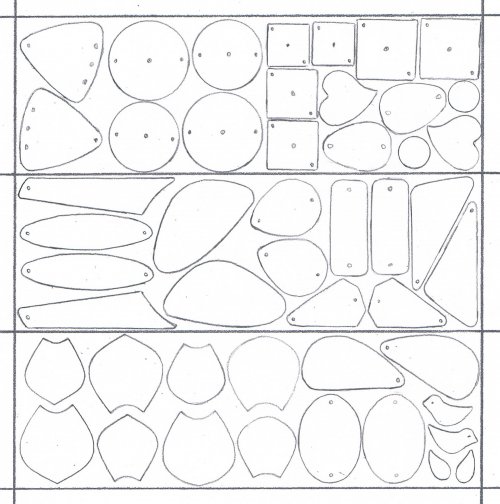

Earring Pairs Template

Earring Pairs Template

Storing and Caring for Files

Storing and Caring for Files

Open or Closed Jump RIngs on Bracelets and Necklaces

Open or Closed Jump RIngs on Bracelets and Necklaces

Versatile Permanent Markers

Versatile Permanent Markers

You Used What

You Used What

Rescuing a Very Used Magnesia Soldering Block

Rescuing a Very Used Magnesia Soldering Block

Using Hole Punch Pliers

Using Hole Punch Pliers

Metal Shears Care

Metal Shears Care

Paperclip Earrings

Paperclip Earrings

Think Outside the Box - Alternative Metal Texturing

Think Outside the Box - Alternative Metal Texturing

Make Stamping Metal a Bit Easier

Make Stamping Metal a Bit Easier

Stone Bezel Setting Tips

Stone Bezel Setting Tips

Viking Knit Tips

Viking Knit Tips

Using Glue Under Cabochons

Using Glue Under Cabochons

Tool Tip - Digital Pocket Scale

Tool Tip - Digital Pocket Scale

Repeat Performance

Repeat Performance

Another Way to Condition a Rawhide Mallet

Another Way to Condition a Rawhide Mallet

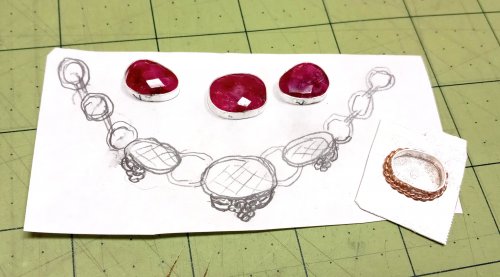

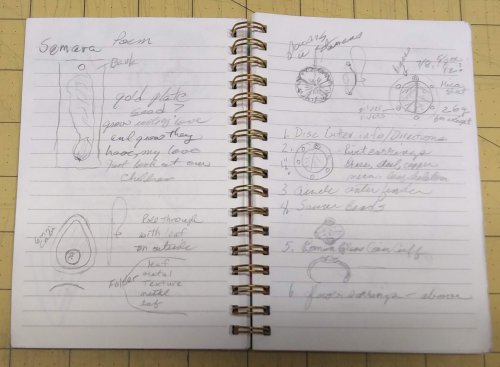

Carry a Sketch Pad

Carry a Sketch Pad

Why You Should Take a Class

Why You Should Take a Class

Jewelry Making Templates

Jewelry Making Templates

Carry a Sketch Pad

Carry a Sketch Pad

Keeping Your Bracelet Focals in Place

Keeping Your Bracelet Focals in Place

Metal Content Stamping

Metal Content Stamping

Using Sanding Sponges and Papers

Using Sanding Sponges and Papers

Adding Depth to Carved Beads and Cabochons

Adding Depth to Carved Beads and Cabochons

Closing Rings Tightly for Soldering

Closing Rings Tightly for Soldering

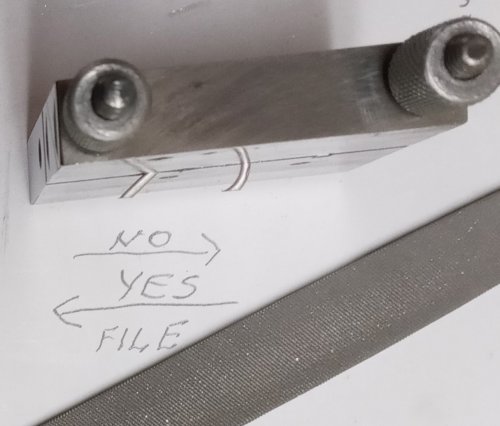

Squaring Wire Ends

Squaring Wire Ends

Ring Mandrels

Ring Mandrels

Tool Tip - Bench Brushes

Tool Tip - Bench Brushes

Scrap Wire Twisted Rings

Scrap Wire Twisted Rings

Tool Tip - Soft Bristle Metal Brushes

Tool Tip - Soft Bristle Metal Brushes

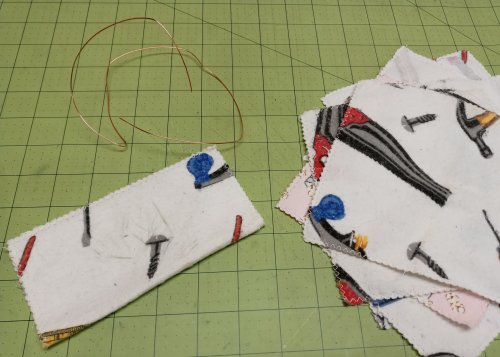

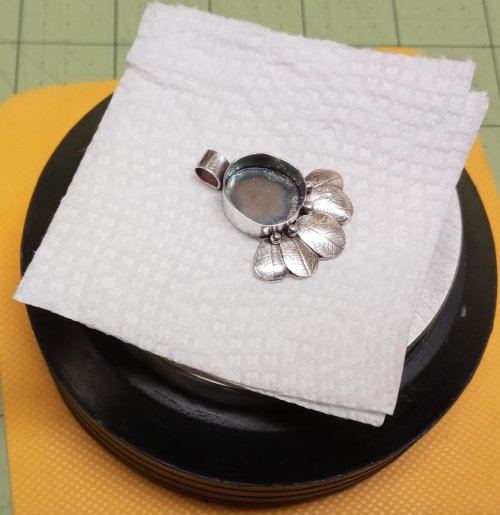

Project Multiples - Calibrated Cabochons

Project Multiples - Calibrated Cabochons

Mobius Pearl Drop Earrings

Mobius Pearl Drop Earrings

Copper Wire Solder

Copper Wire Solder

Large Dapping Punches and Alternatives

Large Dapping Punches and Alternatives

Project Multiples - Glass Pebble Cabs

Project Multiples - Glass Pebble Cabs

Project Storage

Project Storage

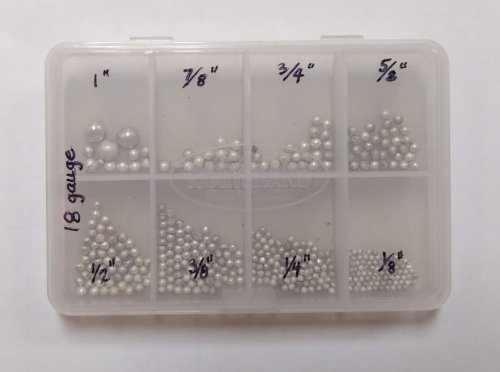

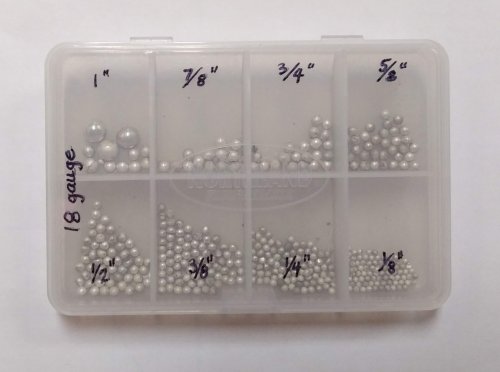

Tiny Bead and Findings Storage

Tiny Bead and Findings Storage

Working Smart

Working Smart

Display Trays as Storage

Display Trays as Storage

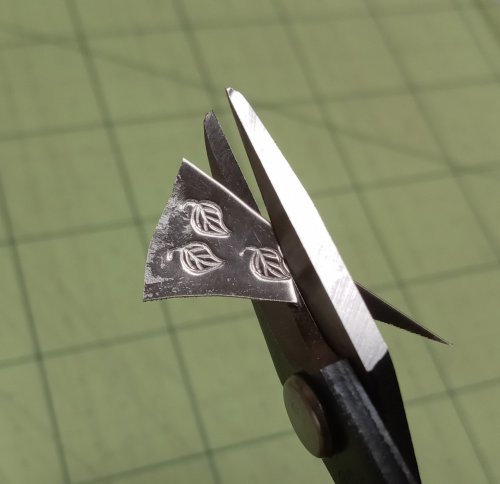

Making TIny Leaves

Making TIny Leaves

Adapting a Tutorial

Adapting a Tutorial

Build Better Bead Storage

Build Better Bead Storage

Using Magical Crimping Pliers

Using Magical Crimping Pliers

Add a Touch of Gold

Add a Touch of Gold

Make a Lacy Argentium Scrap Metal Sheet

Make a Lacy Argentium Scrap Metal Sheet

Birch Bark Texture

Birch Bark Texture

Versatile Snap-on Bails

Versatile Snap-on Bails

Bead Cap Primer

Bead Cap Primer

Using Glue Sticks with Printed Templates

Using Glue Sticks with Printed Templates

Choosing a Lake or Riverstone

Choosing a Lake or Riverstone

Do a Facebook Collaboration

Do a Facebook Collaboration

Shielding a Jewelry Piece When Stone Setting

Shielding a Jewelry Piece When Stone Setting

Some Ideas Are Right in Front of You

Some Ideas Are Right in Front of You

Curving and Scrolling Wire

Curving and Scrolling Wire

Using Snapsets to Add Sparkle to Your Work

Using Snapsets to Add Sparkle to Your Work

Cutting Wire Multiples of the Same Length

Cutting Wire Multiples of the Same Length

Separating Distinct Textures on a Single Piece of Metal

Separating Distinct Textures on a Single Piece of Metal

Changing the Size of a Pearl

Changing the Size of a Pearl

Easy Ring Cleaning

Easy Ring Cleaning

Add a Bit of Dimension

Add a Bit of Dimension

Keeping Projects Separate

Keeping Projects Separate

Tumbling and Polishing Metal Beads

Tumbling and Polishing Metal Beads

Unexpected Jewels

Unexpected Jewels

Saws and Turning Radius

Saws and Turning Radius

Flattening Metal Pieces

Flattening Metal Pieces

Mobius Ring Spacers

Mobius Ring Spacers

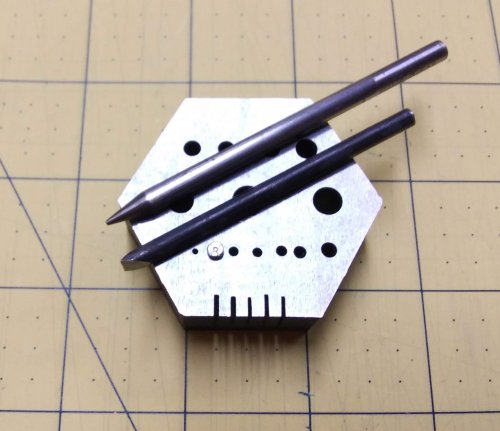

Filing Angled Wires in a Jig

Filing Angled Wires in a Jig

Storing Handmade Elements

Storing Handmade Elements

Simple Way to Straighten Wire

Simple Way to Straighten Wire

Two Ways to Make Simple Loops

Two Ways to Make Simple Loops

Making Simple Eyepins

Making Simple Eyepins

Using Fun Tak as a Resist

Using Fun Tak as a Resist

Why Use a Binder to Store Embellishments

Why Use a Binder to Store Embellishments

Storing Dapping Blocks and Punches

Storing Dapping Blocks and Punches

Wire Basics - Opening and Closing Jump Rings

Wire Basics - Opening and Closing Jump Rings

Enlarging a Bezel

Enlarging a Bezel

Leaf Inspirations

Leaf Inspirations

Earring Findings for Different Ages

Earring Findings for Different Ages

Accidentally Learning Something New

Accidentally Learning Something New

Fusing Jump Rings

Fusing Jump Rings

Tool Tip - Divided Caliper Scribe

Tool Tip - Divided Caliper Scribe

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Rethinking a Design

Rethinking a Design

When Bead Holes are Too Large

When Bead Holes are Too Large

Eye of Shiva AKA Pacific Cat's Eye

Eye of Shiva AKA Pacific Cat's Eye

Ribbon Wrapped Bracelet tips

Ribbon Wrapped Bracelet tips

Making Lightweight Earrings with Unexpected Finds

Making Lightweight Earrings with Unexpected Finds

Tool Tip - Indispensable Tapes

Tool Tip - Indispensable Tapes

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

Aha Lightbulb Moment

Aha Lightbulb Moment

Adding Loops for Dangles on a Classic Wire Bezel Wrap

Adding Loops for Dangles on a Classic Wire Bezel Wrap

After the Rain - Found Treasures

After the Rain - Found Treasures

Back to School

Back to School

Bezel Solution for Corners and Points

Bezel Solution for Corners and Points

Filling Holes in Stones

Filling Holes in Stones

Dots to the Rescue

Dots to the Rescue

Raising Stones in Bezel Settings

Raising Stones in Bezel Settings

Leveling the Bottom of a Large Bezel

Leveling the Bottom of a Large Bezel

Using Leftovers

Using Leftovers

Make-do Sawing Solutions

Make-do Sawing Solutions

Combining Tutorials

Combining Tutorials

Scrap Melt

Scrap Melt

What's Your Jewelry Style

What's Your Jewelry Style

Using Wax from Braces

Using Wax from Braces

Sometimes Simple Really is Better

Sometimes Simple Really is Better

Bead Soup and Small Changes

Bead Soup and Small Changes

Repurposing Sterling Cord End Findings

Repurposing Sterling Cord End Findings

Wire Wrapped Bail Finishing Options

Wire Wrapped Bail Finishing Options

Protecting The Back of a Piece When Setting Stones

Protecting The Back of a Piece When Setting Stones

Altering Your Dapping Block

Altering Your Dapping Block

Trimming Around a Bezel

Trimming Around a Bezel

Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves

Labeling Cabs When Working with Them

Labeling Cabs When Working with Them

Basic Round Well Wood Dapping Blocks

Basic Round Well Wood Dapping Blocks

Get Inspired by What's on Your Bench

Get Inspired by What's on Your Bench

When Things Go Awry

When Things Go Awry

Putting On and Taking Off a Cuff Bracelet

Putting On and Taking Off a Cuff Bracelet

Adding Hearts to Your Designs

Adding Hearts to Your Designs

Taking Care of Your Rolling Mill

Taking Care of Your Rolling Mill

Power Up

Power Up

Hammer Basics

Hammer Basics

Wire Temper and Jump Rings

Wire Temper and Jump Rings

Embellish Bezels with Twisted Wire

Embellish Bezels with Twisted Wire

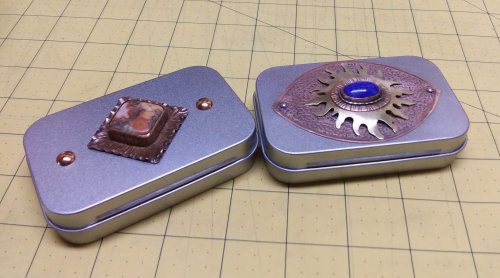

Embellish a Treasure Box

Embellish a Treasure Box

Make a Polymer Clay Cabochon Mandrel

Make a Polymer Clay Cabochon Mandrel

Jewelry Packaging for Small Items - Pillow Boxes

Jewelry Packaging for Small Items - Pillow Boxes

Make-do Sawing Solutions

Make-do Sawing Solutions

Ball Chain Embellishments

Ball Chain Embellishments

Pickling and Super Pickle

Pickling and Super Pickle

A Better T-bar

A Better T-bar

A Better Way to Change a Saw Blade

A Better Way to Change a Saw Blade

Making Consistent Hanging Loops

Making Consistent Hanging Loops

Targeted Patina

Targeted Patina

Coin Focal Inspiration

Coin Focal Inspiration

Bracelet and Paperclip Trick

Bracelet and Paperclip Trick

What Wire is Best for Earring Findings

What Wire is Best for Earring Findings

Storing Your Metal Stamps

Storing Your Metal Stamps

Save Those Old Buttons

Save Those Old Buttons

Adjusting Purchased Ear Wires

Adjusting Purchased Ear Wires

Twisted Wire Tips

Twisted Wire Tips

Stash Inspiration and Notes

Stash Inspiration and Notes

Short Quotes for Stamped Jewelry

Short Quotes for Stamped Jewelry

My Favorite Tweezers

My Favorite Tweezers

No Rolling Mill- No Problem

No Rolling Mill- No Problem

Coiling Wire for Jump Rings

Coiling Wire for Jump Rings

Cutting Coils Into Jump Rings

Cutting Coils Into Jump Rings

Closed Jump Rings Soldering vs Fusing

Closed Jump Rings Soldering vs Fusing

Recycling Scrap Into Sheet Metal

Recycling Scrap Into Sheet Metal