Jump Ring Rescue

Shall I make it dramatic? So, there I was, making a paper clip chain and I sawed my jump rings wonky. Filing was going to be needed, but how was I going to file the ends of these small jump rings, without screwing them up further? What to do? What to do?

Instructions

It wasn't really dramatic but it was as dilemma.

What do you do when you are cutting jump rings to make chain or because you want to solder them closed and your ends are not smooth? This can happen with both a saw and definitely with flush cutters.

You cannot solder a jump ring closed if you do not have a smooth butt joint.

Solder will not fill a gap.

If you file, unguided by hand (and yes, I've done this too), you can end up filing forever, never getting a flat surface.

My jump ring is too small and wrong size to fit in a miter vice.

What do you do when you are cutting jump rings to make chain or because you want to solder them closed and your ends are not smooth? This can happen with both a saw and definitely with flush cutters.

You cannot solder a jump ring closed if you do not have a smooth butt joint.

Solder will not fill a gap.

If you file, unguided by hand (and yes, I've done this too), you can end up filing forever, never getting a flat surface.

My jump ring is too small and wrong size to fit in a miter vice.

What I've come up with is parallel jaw pliers and needle files.

Before using my parallel jaw pliers, I did take a big file and file the ends flat and shiny.

I didn't want the pliers to mar my jump ring.

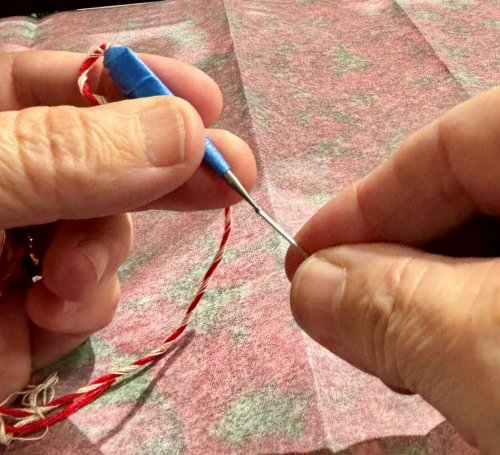

Twist the jump ring open, open enough to get a small file in there without touching any other part of the jump ring.

Place jump ring in the pliers with the open end perpendicular to the top of the pliers.

I look out the window, to get a clear and bright view of the end of my jump ring in relation to the end of the pliers.

To make this process simpler, I did ben the top of the jump ring (cut side) flat.

This allows me to line up the ends for a better solder seam.

After flattening, it looks like a "D". After soldering, I use a mandrel and a nylon mallet to round it out again.

Before using my parallel jaw pliers, I did take a big file and file the ends flat and shiny.

I didn't want the pliers to mar my jump ring.

Twist the jump ring open, open enough to get a small file in there without touching any other part of the jump ring.

Place jump ring in the pliers with the open end perpendicular to the top of the pliers.

I look out the window, to get a clear and bright view of the end of my jump ring in relation to the end of the pliers.

To make this process simpler, I did ben the top of the jump ring (cut side) flat.

This allows me to line up the ends for a better solder seam.

After flattening, it looks like a "D". After soldering, I use a mandrel and a nylon mallet to round it out again.

Then, hands braced...you can use your bench or your bench pin, whichever is most comfortable for you, file the ends of your jump ring flat.

Double check to make sure it's flat.

There you go, an easy way to make certain you get a good clean and flat seam to solder for jump rings.

I used this method with 12mm, 10mm and 6mm jump rings in making my paper clip chain.

Double check to make sure it's flat.

There you go, an easy way to make certain you get a good clean and flat seam to solder for jump rings.

I used this method with 12mm, 10mm and 6mm jump rings in making my paper clip chain.

Materials

20 Gauge Round Half Hard .925 Sterling Silver Wire

H8-20H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $6.75

- Gold Club Price: $5.06

18 Gauge Round Half Hard .925 Sterling Silver Wire

H8-18H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $9.82

- Gold Club Price: $7.36

Tools

7 Inch Coil Cutting Jump Ring Making Plier with PVC Comfort Grips - Pack of 1

G2-110

- G2-110

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

The Quad Jump Ring Former

DUR-1312

- DUR-1312

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $388.00

- Gold Club Price: $291.00

Wubbers Round Mandrel Pliers - 5 Plier Set

G15-18

- G15-18

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $149.95

- Gold Club Price: $112.46

- Category: General Education

- Technique(s): General Education

Making Bead Link Chain

Making Bead Link Chain

Acculoop Precision Pliers Ear Wires

Acculoop Precision Pliers Ear Wires

Using Mandrels for Making Jump Rings

Using Mandrels for Making Jump Rings

Jump Ring Tips

Jump Ring Tips

Working with Annealed Steel Wire

Working with Annealed Steel Wire

Patina Tips and Tricks for Copper

Patina Tips and Tricks for Copper

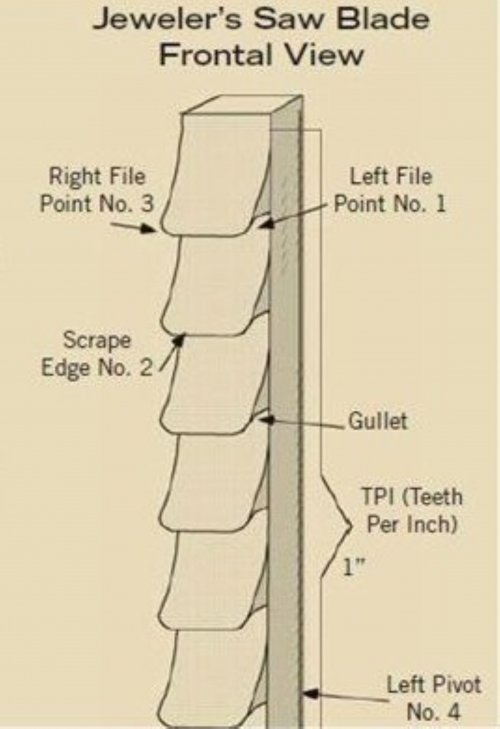

Sawing and Filing Safety Tips

Sawing and Filing Safety Tips

Creating on the Go

Creating on the Go

Riveting Tips

Riveting Tips

Texture Summer School

Texture Summer School

Reproducing Designs

Reproducing Designs

Up Your Design Game with Flat Wire

Up Your Design Game with Flat Wire

Sawing Tiny Shapes

Sawing Tiny Shapes

Quick Ring Shank Sizing

Quick Ring Shank Sizing

Stabilizing a Large Hole Bead

Stabilizing a Large Hole Bead

Protect Your Sharp Tools and Your Fingers

Protect Your Sharp Tools and Your Fingers

Tiny Chain Link Fix

Tiny Chain Link Fix

Organized Storage for Wire

Organized Storage for Wire

Taking Risks

Taking Risks

Centering Your Stamp Patterns

Centering Your Stamp Patterns

Stamping Tips for Success

Stamping Tips for Success

Finding My Place, a Bangle Tip

Finding My Place, a Bangle Tip

No Time for Pickling

No Time for Pickling

Eye Pin Dilemma

Eye Pin Dilemma

It's a Fit Issue

It's a Fit Issue

Flux Fix

Flux Fix

Using Templates in Jewelry Making

Using Templates in Jewelry Making

Chain Maintenance

Chain Maintenance

Bracing For It

Bracing For It

A Weighty Matter

A Weighty Matter

Altering an Existing Chain - From Paperclip to Petal Links

Altering an Existing Chain - From Paperclip to Petal Links

Essential Sawing Tips

Essential Sawing Tips

Choosing the Right Saw Blade Part 1

Choosing the Right Saw Blade Part 1

Choosing the Right Saw Blade Part 2

Choosing the Right Saw Blade Part 2

Wire Guard Tip

Wire Guard Tip

Getting the Ring Shank Size Right

Getting the Ring Shank Size Right

Drilling on Curved Metal

Drilling on Curved Metal

Heat Rivet Repair

Heat Rivet Repair

Making It Work

Making It Work

Consistent Earwire Pairs

Consistent Earwire Pairs

Ear Wires on the Fly

Ear Wires on the Fly

Production Mode

Production Mode

Sputtering Torch

Sputtering Torch

Nylon Hammer Remodel

Nylon Hammer Remodel

Saved by Scotch Tape

Saved by Scotch Tape

Pro Polish Pad

Pro Polish Pad

Labels Make the World Go Around

Labels Make the World Go Around

I Spy a Bit

I Spy a Bit

The Magic of Double Stick Tape

The Magic of Double Stick Tape