Embellish Bezels with Twisted Wire

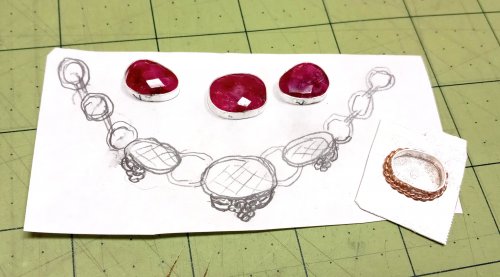

A bit more gold in the form of a twisted "rope" around the necklace bezels was all that was needed for a more finished look.

FYI: The gold-filled embellishments are charms and bead caps that have been shaped and embellished to use in the design.

Ah, that makes sense fitting the twisted wire before soldering the bezel and frame lets you fine-tune everything while it's still flexible. Especially when you're planning on layering more elements later, it's probably easier to get those parts aligned perfectly in the early stages.

Do you find that pre-fitting helps prevent distortion or misalignment as you build up the layers? Or is it more about saving time and avoiding extra adjustments after soldering?.

Ah, got it! Since the stones aren't flat-back cabochons, shaping the twisted wire around them before soldering could indeed risk warping or distorting the bezel edges. That's a tricky balance wanting the twisted wire frame to fit perfectly, but also needing to protect the integrity of the bezel, especially if it has a curved or uneven base.

In that case, do you usually fit the wire after soldering the bezel in place on the backplate to avoid any unwanted bending? Or do you have any special tricks to shape the wire delicately without stressing the bezel?

The EASIEST way to work with the bezel is to solder it in place on a backplate first, then add the twisted wire frame.

Absolutely! Reading through the entire tutorial before starting is key not just to understand the steps but to prepare mentally and physically for the process. And safety first, always!

Know your workspace ventilation, lighting, clear surfaces.

Familiarize yourself with the tools and materials, especially if they involve chemicals, heat, or sharp edges.

Wear the right protective gear: gloves, goggles, masks, etc., depending on the task.

Keep your workspace organized and clutter-free to avoid accidents.

Are you gearing up for a specific project right now?

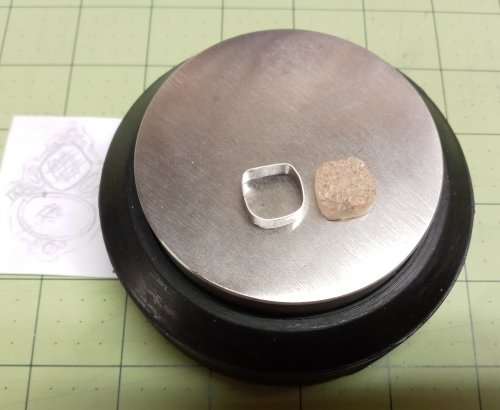

Make bezels for the stones being used. Solder them in place on the backplates. Since Argentium is used here, there is no need to pickle.

If sterling silver is being used, the piece must be pickled, neutralized in baking soda water, rinsed again, and dried before continuing.

That's a classic technique for making a uniform twisted rope wire! Using a single long piece folded in half ensures the two strands twist evenly together, giving a consistent look and strength.

By inserting the fold into the drill and twisting, you get that beautiful rope effect quickly and with minimal effort compared to hand-twisting.

How long do you usually twist your wire, or do you have a particular length or tightness you aim for? And do you anneal the wire before or after twisting to keep it from breaking?

If the two wires are not twisted together tightly enough, they will separate and come apart when cut in short lengths. However, it should not be twisted so tightly that it no longer looks like a rope.

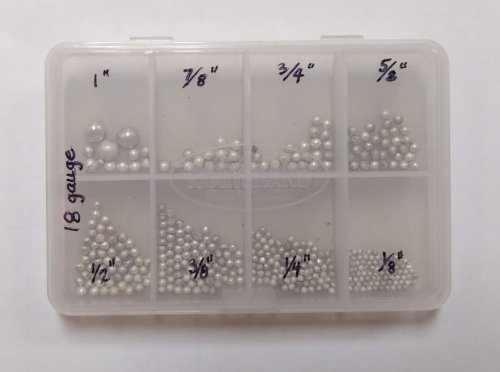

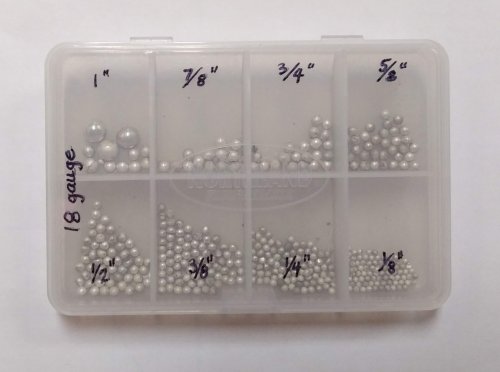

Try upping your game: Measure the diameter of the twisted wires.

Choose another plain round wire that is the same diameter and length. Anneal it. Twist the two wires together.

It may be easier to do this if the ends of one wire are soldered to the other wire first.

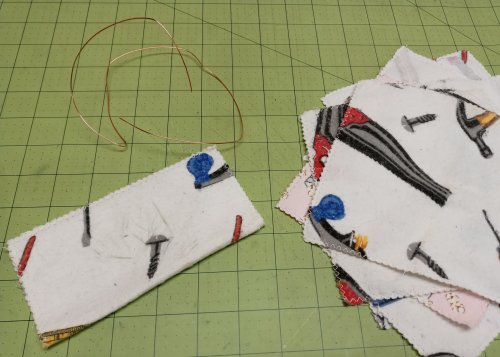

Twisting wire work hardens it. It must be annealed to make it easier to shape around smaller bezels.

Argentium does not need to be fluxed, but all other metals can be fluxed to prevent fire scale.

Personally, I flux anything gold-filled, whether it is alone or is on the top or the bottom of a piece being heated.

When the twisted wire ends will be covered with embellishments, it does not matter what they look like.

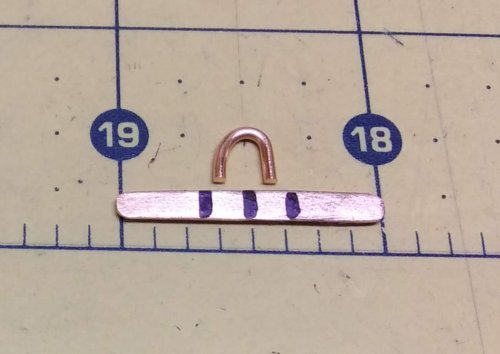

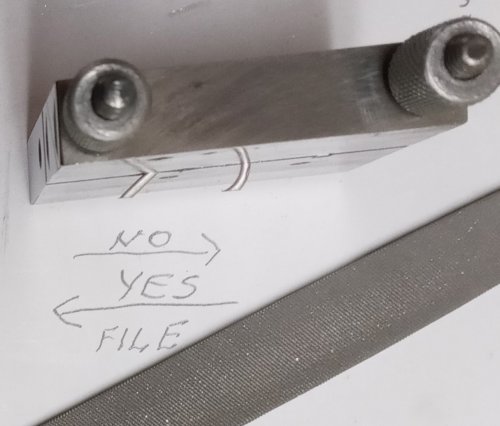

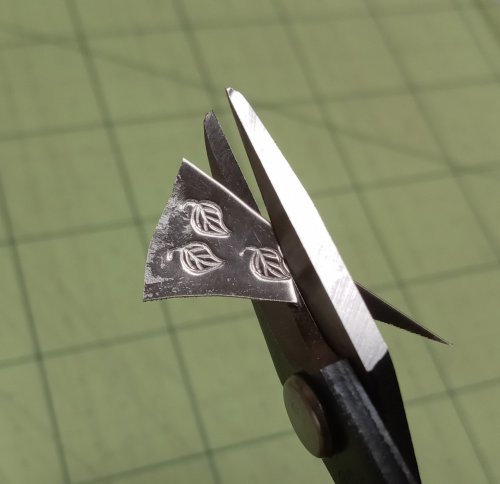

Flush cut the ends and they will be fine, like the top twisted wire in the first photo.

Examples of flush cut twisted wires in use are in the second photo.

However, when the full circumference of the twisted wire around the bezel will show, it is important to disguise the cut ends.

Cut the twisted wire ends at an angle, following a twist line - blue lines on the middle wire in the first photo.

When the ends are overlapped, the cut will seem to disappear-blue arrow on the ring in the first photo.

Examples of flush cut twisted wires in use are in the third photo.

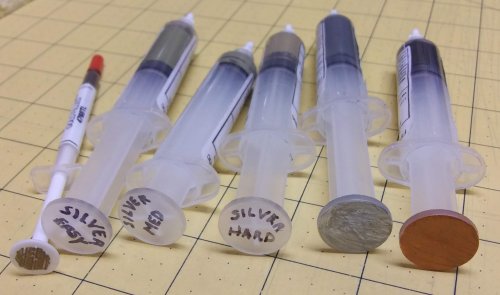

Hard solder will not flow until after Argentium reaches its melting point.

Since I use Argentium sheet and wire, the only time hard solder can be used is on a bezel seam.

This must be kept in mind when connecting layers and pieces together in multiple steps.

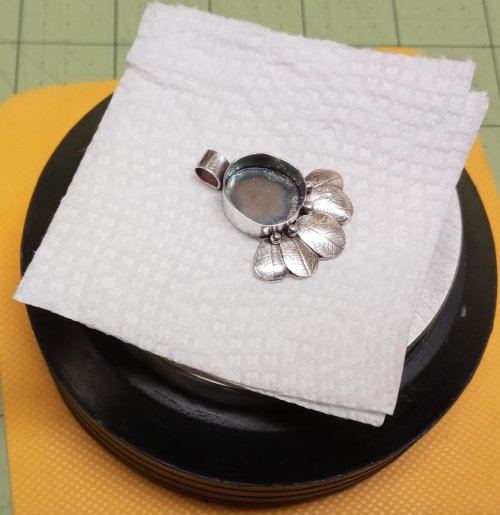

Here, the fine silver bezel has already been soldered in place on an Argentium backplate using medium paste solder.

The piece is clean and ready to be worked with.

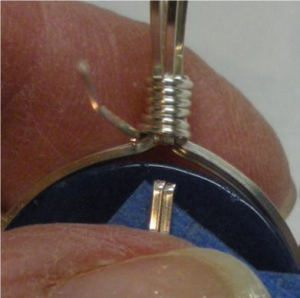

Loosely wrap the twisted wire around the bezel.

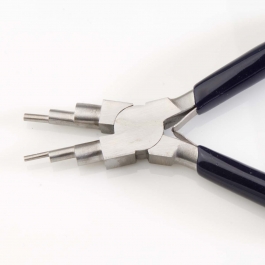

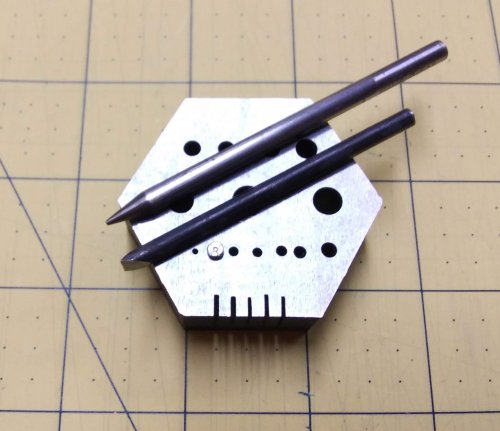

Cut a piece a bit longer than needed. Shape the wire to fit the bezel using small or large Wrap "N" Tap pliers and flat nose soft jaw pliers.

The cylinder sides of the Wrap "N" Tap pliers will help curve the wire while the padded side prevents the twisted wire from being compressed in any way.

It is easiest to overlap the wire ends on the longest straight side -arrows in the first photo - or where they may be less noticeable - by the loops in the second photo.

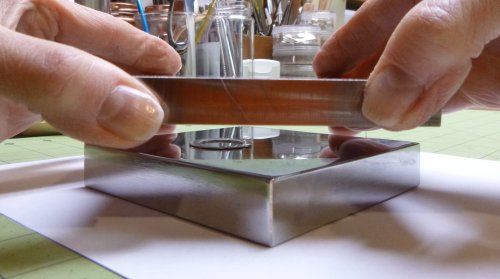

Place the twisted wire frame around the bezel.

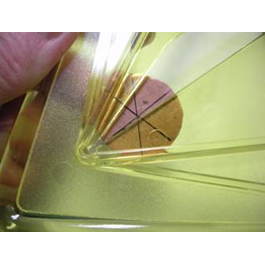

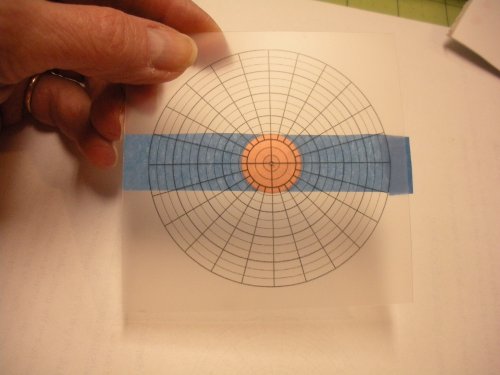

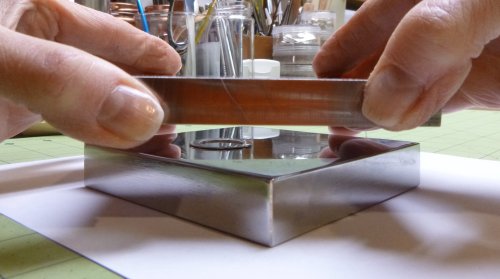

Use an ultra-fine point retractable Sharpie to mark the backplate where the twisted wire frame ends will overlap - first photo.

Remove the twisted wire frame.

Place dots of medium paste solder on the backplate around the outside of the bezel, with a bit extra at the overlap site.

Note: Yes, medium paste solder has already been used to secure the bezel to the backplate.

There will be no problems using it again to secure the frame in place.

Press the frame into place making sure to press the frame overlap into the extra solder. This will solder the ends together.

Use a paper towel or Q-Tip to push the dots of paste solder under the twisted wire and into it.

Use a toothpick to remove excess paste solder left on the backplate around the outside of the frame.

Place the assembly on a soldering surface. Use a torch head on a butane canister to heat the piece until the solder flows.

Since solder follows heat and paste solder for silver is being used, be very careful to not pull the solder up over the gold-filled wire.

Also remember, flux will help prevent fire scale.

Pickle the piece, then neutralize it in baking soda water and rinse it again. Dry the piece before continuing.

Check for any loose areas on the frame that may need to be soldered again.

Repeat the step above if needed.

If embellishments are to be added, use easy paste solder.

If the embellishments must be added in two steps, it is fine to use easy solder in both steps.

Materials

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 5FT

- Price: $20.00

- Gold Club Price: $15.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 5FT

- Price: $34.42

- Gold Club Price: $25.81

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $22.17

- Gold Club Price: $16.63

Tools

- G5-15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $42.97

- Gold Club Price: $32.23

- PLR-487.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.97

- Gold Club Price: $12.73

- PLR-746.03

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

- TRCH-1002

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $74.95

- Gold Club Price: $56.21

- MAT-500.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $116.97

- Gold Club Price: $87.73

- Category: Metalwork

- Technique(s): Butane Torch Techniques, Twisting

Cleaning Your Jewelry

Cleaning Your Jewelry

Build A Tool Rack

Build A Tool Rack

Clamps for Jewelry Making

Clamps for Jewelry Making

Finishing Wire Ends

Finishing Wire Ends

Handmade Closures

Handmade Closures

Removing Tarnish From Your Jewelry

Removing Tarnish From Your Jewelry

Homemade Pickle

Homemade Pickle

Wire Wrapped Loops

Wire Wrapped Loops

How to Make Balled Head Pins

How to Make Balled Head Pins

Lessen the Noise - Save Your Eardrums

Lessen the Noise - Save Your Eardrums

Make a Rivet and Eyelet Tile

Make a Rivet and Eyelet Tile

Two Tips for Making Pendant Bails with Craft Wire

Two Tips for Making Pendant Bails with Craft Wire

Petal Forming on a Wood Block

Petal Forming on a Wood Block

Save Your Fingers while Texturing

Save Your Fingers while Texturing

Soldering on Copper

Soldering on Copper

Sticker Templates

Sticker Templates

Using 6 Step Barrel Pliers

Using 6 Step Barrel Pliers

Using a Center Finder

Using a Center Finder

Using a Tile to Cut Rivets

Using a Tile to Cut Rivets

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Tiles on Tube Rivets and Eyelets

Using Tiles on Tube Rivets and Eyelets

Clothespin Tools

Clothespin Tools

Making Decorative Granulation Beads

Making Decorative Granulation Beads

Using Your Hole Punch Pliers

Using Your Hole Punch Pliers

Decorative Granulation and Beads

Decorative Granulation and Beads

How to Find and Mark the Center of a Disc.

How to Find and Mark the Center of a Disc.

Choosing the Right Clasp

Choosing the Right Clasp

Chunky Chain Inspiration

Chunky Chain Inspiration

Tool Tip - Steampunk or Industrial Rivets

Tool Tip - Steampunk or Industrial Rivets

Storing Jump Rings

Storing Jump Rings

Wear Your Brooches on a Neckwire

Wear Your Brooches on a Neckwire

Storing Your Metal

Storing Your Metal

Using Disc Cutter Shims

Using Disc Cutter Shims

Conditioning a Rawhide Mallet

Conditioning a Rawhide Mallet

Flattening Metal Pieces

Flattening Metal Pieces

Quenching

Quenching

Saving a Broken Solder Brick

Saving a Broken Solder Brick

Why I Use Solder Paste

Why I Use Solder Paste

Designing a Toggle Clasp That Works

Designing a Toggle Clasp That Works

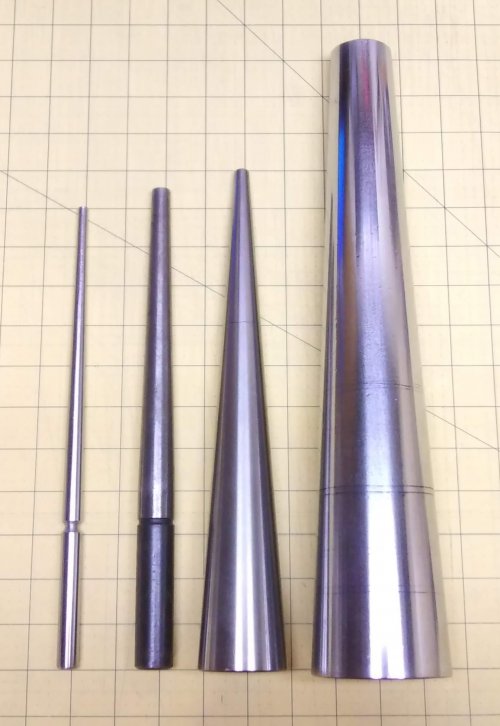

Round Mandrels

Round Mandrels

Get the Look of Eyelets

Get the Look of Eyelets

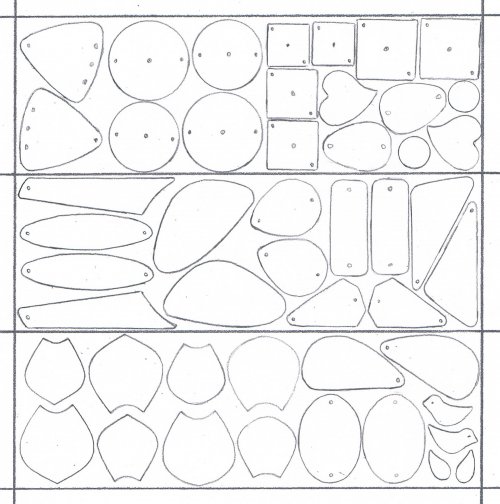

Earring Pairs Template

Earring Pairs Template

Storing and Caring for Files

Storing and Caring for Files

Open or Closed Jump RIngs on Bracelets and Necklaces

Open or Closed Jump RIngs on Bracelets and Necklaces

Versatile Permanent Markers

Versatile Permanent Markers

You Used What

You Used What

Rescuing a Very Used Magnesia Soldering Block

Rescuing a Very Used Magnesia Soldering Block

Using Hole Punch Pliers

Using Hole Punch Pliers

Metal Shears Care

Metal Shears Care

Paperclip Earrings

Paperclip Earrings

Think Outside the Box - Alternative Metal Texturing

Think Outside the Box - Alternative Metal Texturing

Make Stamping Metal a Bit Easier

Make Stamping Metal a Bit Easier

Stone Bezel Setting Tips

Stone Bezel Setting Tips

Viking Knit Tips

Viking Knit Tips

Using Glue Under Cabochons

Using Glue Under Cabochons

Tool Tip - Digital Pocket Scale

Tool Tip - Digital Pocket Scale

Repeat Performance

Repeat Performance

Another Way to Condition a Rawhide Mallet

Another Way to Condition a Rawhide Mallet

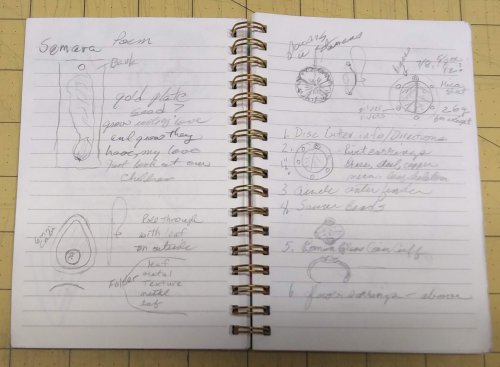

Carry a Sketch Pad

Carry a Sketch Pad

Why You Should Take a Class

Why You Should Take a Class

Jewelry Making Templates

Jewelry Making Templates

Carry a Sketch Pad

Carry a Sketch Pad

Keeping Your Bracelet Focals in Place

Keeping Your Bracelet Focals in Place

Metal Content Stamping

Metal Content Stamping

Using Sanding Sponges and Papers

Using Sanding Sponges and Papers

Adding Depth to Carved Beads and Cabochons

Adding Depth to Carved Beads and Cabochons

Closing Rings Tightly for Soldering

Closing Rings Tightly for Soldering

Squaring Wire Ends

Squaring Wire Ends

Ring Mandrels

Ring Mandrels

Tool Tip - Bench Brushes

Tool Tip - Bench Brushes

Scrap Wire Twisted Rings

Scrap Wire Twisted Rings

Tool Tip - Soft Bristle Metal Brushes

Tool Tip - Soft Bristle Metal Brushes

Project Multiples - Calibrated Cabochons

Project Multiples - Calibrated Cabochons

Mobius Pearl Drop Earrings

Mobius Pearl Drop Earrings

Copper Wire Solder

Copper Wire Solder

Large Dapping Punches and Alternatives

Large Dapping Punches and Alternatives

Project Multiples - Glass Pebble Cabs

Project Multiples - Glass Pebble Cabs

Project Storage

Project Storage

Tiny Bead and Findings Storage

Tiny Bead and Findings Storage

Working Smart

Working Smart

Display Trays as Storage

Display Trays as Storage

Making TIny Leaves

Making TIny Leaves

Adapting a Tutorial

Adapting a Tutorial

Build Better Bead Storage

Build Better Bead Storage

Using Magical Crimping Pliers

Using Magical Crimping Pliers

Add a Touch of Gold

Add a Touch of Gold

Make a Lacy Argentium Scrap Metal Sheet

Make a Lacy Argentium Scrap Metal Sheet

Birch Bark Texture

Birch Bark Texture

Versatile Snap-on Bails

Versatile Snap-on Bails

Bead Cap Primer

Bead Cap Primer

Using Glue Sticks with Printed Templates

Using Glue Sticks with Printed Templates

Choosing a Lake or Riverstone

Choosing a Lake or Riverstone

Do a Facebook Collaboration

Do a Facebook Collaboration

Shielding a Jewelry Piece When Stone Setting

Shielding a Jewelry Piece When Stone Setting

Some Ideas Are Right in Front of You

Some Ideas Are Right in Front of You

Curving and Scrolling Wire

Curving and Scrolling Wire

Using Snapsets to Add Sparkle to Your Work

Using Snapsets to Add Sparkle to Your Work

Cutting Wire Multiples of the Same Length

Cutting Wire Multiples of the Same Length

Separating Distinct Textures on a Single Piece of Metal

Separating Distinct Textures on a Single Piece of Metal

Changing the Size of a Pearl

Changing the Size of a Pearl

Easy Ring Cleaning

Easy Ring Cleaning

Add a Bit of Dimension

Add a Bit of Dimension

Keeping Projects Separate

Keeping Projects Separate

Tumbling and Polishing Metal Beads

Tumbling and Polishing Metal Beads

Unexpected Jewels

Unexpected Jewels

Saws and Turning Radius

Saws and Turning Radius

Flattening Metal Pieces

Flattening Metal Pieces

Mobius Ring Spacers

Mobius Ring Spacers

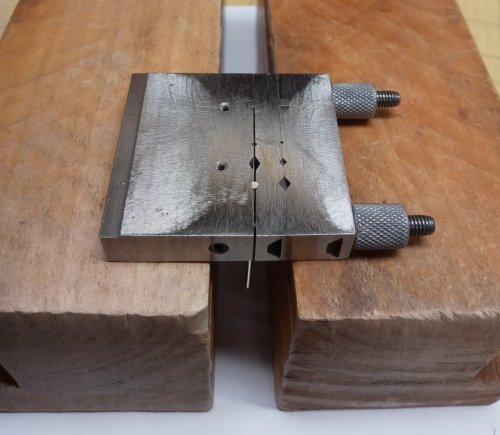

Filing Angled Wires in a Jig

Filing Angled Wires in a Jig

Storing Handmade Elements

Storing Handmade Elements

Simple Way to Straighten Wire

Simple Way to Straighten Wire

Two Ways to Make Simple Loops

Two Ways to Make Simple Loops

Making Simple Eyepins

Making Simple Eyepins

Using Fun Tak as a Resist

Using Fun Tak as a Resist

Why Use a Binder to Store Embellishments

Why Use a Binder to Store Embellishments

Storing Dapping Blocks and Punches

Storing Dapping Blocks and Punches

Wire Basics - Opening and Closing Jump Rings

Wire Basics - Opening and Closing Jump Rings

Enlarging a Bezel

Enlarging a Bezel

Leaf Inspirations

Leaf Inspirations

Earring Findings for Different Ages

Earring Findings for Different Ages

Accidentally Learning Something New

Accidentally Learning Something New

Fusing Jump Rings

Fusing Jump Rings

Tool Tip - Divided Caliper Scribe

Tool Tip - Divided Caliper Scribe

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Rethinking a Design

Rethinking a Design

When Bead Holes are Too Large

When Bead Holes are Too Large

Soldering a Dome to a Backplate

Soldering a Dome to a Backplate

Eye of Shiva AKA Pacific Cat's Eye

Eye of Shiva AKA Pacific Cat's Eye

Ribbon Wrapped Bracelet tips

Ribbon Wrapped Bracelet tips

Making Lightweight Earrings with Unexpected Finds

Making Lightweight Earrings with Unexpected Finds

Tool Tip - Indispensable Tapes

Tool Tip - Indispensable Tapes

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

Aha Lightbulb Moment

Aha Lightbulb Moment

Adding Loops for Dangles on a Classic Wire Bezel Wrap

Adding Loops for Dangles on a Classic Wire Bezel Wrap

After the Rain - Found Treasures

After the Rain - Found Treasures

Back to School

Back to School

Bezel Solution for Corners and Points

Bezel Solution for Corners and Points

Filling Holes in Stones

Filling Holes in Stones

Dots to the Rescue

Dots to the Rescue

Raising Stones in Bezel Settings

Raising Stones in Bezel Settings

Leveling the Bottom of a Large Bezel

Leveling the Bottom of a Large Bezel

Using Leftovers

Using Leftovers

Make-do Sawing Solutions

Make-do Sawing Solutions

Combining Tutorials

Combining Tutorials

Scrap Melt

Scrap Melt

What's Your Jewelry Style

What's Your Jewelry Style

Using Wax from Braces

Using Wax from Braces

Sometimes Simple Really is Better

Sometimes Simple Really is Better

Bead Soup and Small Changes

Bead Soup and Small Changes

Repurposing Sterling Cord End Findings

Repurposing Sterling Cord End Findings

Wire Wrapped Bail Finishing Options

Wire Wrapped Bail Finishing Options

Protecting The Back of a Piece When Setting Stones

Protecting The Back of a Piece When Setting Stones

Altering Your Dapping Block

Altering Your Dapping Block

Trimming Around a Bezel

Trimming Around a Bezel

Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves

Labeling Cabs When Working with Them

Labeling Cabs When Working with Them

Basic Round Well Wood Dapping Blocks

Basic Round Well Wood Dapping Blocks

Get Inspired by What's on Your Bench

Get Inspired by What's on Your Bench

When Things Go Awry

When Things Go Awry

Putting On and Taking Off a Cuff Bracelet

Putting On and Taking Off a Cuff Bracelet

Adding Hearts to Your Designs

Adding Hearts to Your Designs

Taking Care of Your Rolling Mill

Taking Care of Your Rolling Mill

Power Up

Power Up

Hammer Basics

Hammer Basics

Wire Temper and Jump Rings

Wire Temper and Jump Rings

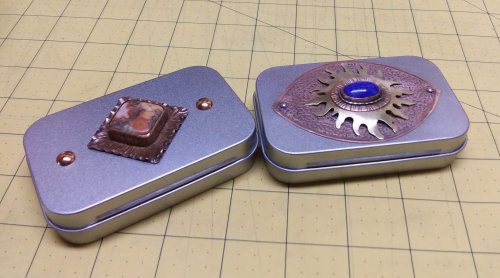

Embellish a Treasure Box

Embellish a Treasure Box

Make a Polymer Clay Cabochon Mandrel

Make a Polymer Clay Cabochon Mandrel

Jewelry Packaging for Small Items - Pillow Boxes

Jewelry Packaging for Small Items - Pillow Boxes

Make-do Sawing Solutions

Make-do Sawing Solutions

Ball Chain Embellishments

Ball Chain Embellishments

Pickling and Super Pickle

Pickling and Super Pickle

A Better T-bar

A Better T-bar

A Better Way to Change a Saw Blade

A Better Way to Change a Saw Blade

Making Consistent Hanging Loops

Making Consistent Hanging Loops

Targeted Patina

Targeted Patina

Coin Focal Inspiration

Coin Focal Inspiration

Bracelet and Paperclip Trick

Bracelet and Paperclip Trick

What Wire is Best for Earring Findings

What Wire is Best for Earring Findings

Storing Your Metal Stamps

Storing Your Metal Stamps

Save Those Old Buttons

Save Those Old Buttons

Adjusting Purchased Ear Wires

Adjusting Purchased Ear Wires

Twisted Wire Tips

Twisted Wire Tips

Stash Inspiration and Notes

Stash Inspiration and Notes

Short Quotes for Stamped Jewelry

Short Quotes for Stamped Jewelry

My Favorite Tweezers

My Favorite Tweezers

No Rolling Mill- No Problem

No Rolling Mill- No Problem

Coiling Wire for Jump Rings

Coiling Wire for Jump Rings

Cutting Coils Into Jump Rings

Cutting Coils Into Jump Rings

Closed Jump Rings Soldering vs Fusing

Closed Jump Rings Soldering vs Fusing

Recycling Scrap Into Sheet Metal

Recycling Scrap Into Sheet Metal