Drilling on Curved Metal

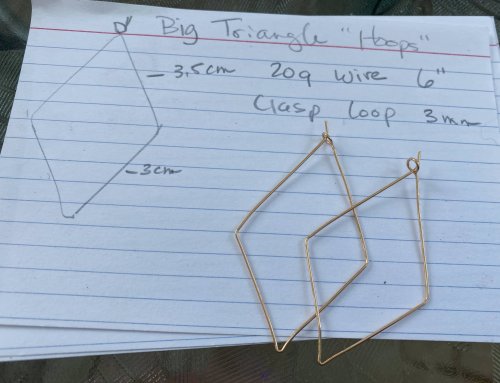

In the studio today, I had hoops on my mind. I used copper sheet metal for the hoop, instead of wire, wanting the width and flatness.

Instructions

I cut out the metal, textured it and formed it. After I was satisfied with the shape of the hoop, I using forming pliers and a dowel... it was time to add the holes in which I would add some dangles.

During the forming of the hoops, I used a dapping punch set up in the vise to curve the edges of the copper inwards.

During the forming of the hoops, I used a dapping punch set up in the vise to curve the edges of the copper inwards.

What I found was I could not use a hole punch pliers to get what I needed and where.

I looked at my 4-hole metal punch, which would not work either.

I did not have space with either tool to accommodate the curve I had added to the metal.

I did not have space with either tool to accommodate the curve I had added to the metal.

Second issue: I couldn't lay the hoop on a piece of wood and fit my flex shaft handpiece inside the hoop to drill the holes I needed.

Just as I was about to lose patience, worried I'd messed up the order of operations and had to start over, I spotted a 1" round wooden dowel on my table.

Just as I was about to lose patience, worried I'd messed up the order of operations and had to start over, I spotted a 1" round wooden dowel on my table.

I still had my small vise set up from forming the hoops, so I clamped the dowel in it and it worked perfectly!

I had already marked the copper where I wanted to drill the holes.

I had already marked the copper where I wanted to drill the holes.

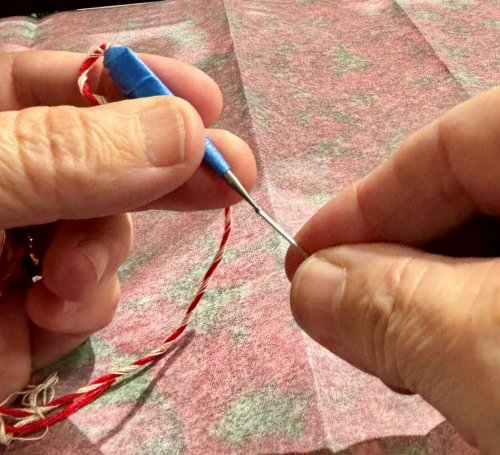

To make certain that the drill bit did not skip around and mar the metal, I added a tiny divot to the metal.

I used a #67 (.81mm for 20g wire) drill bit and carefully drilled the holes I needed.

Being able to access the hoop from the bottom worked like a dream and was very safe.

Being able to access the hoop from the bottom worked like a dream and was very safe.

After the drilling was done, I used an abrasive wheel to take the burrs left from drilling out (Photo 4), leaving the metal smooth and ready for patina, dangles and ear wires.

Hope this helps with your next hoop project!

Materials

No materials listed

Tools

Bench Vise, 2 Inch Jaws

VIS-204.20

- VIS-204.20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.95

- Gold Club Price: $10.46

Eurotool Flex Shaft System 1/6 Horsepower with Reversible Motor

HDP-180.00

- HDP-180.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $169.95

- Gold Club Price: $127.46

20 pc. 61-80 Small Gauge Drill Bits

G26-60

- G26-60

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $4.97

- Gold Club Price: $3.73

Wooden dowel needed size

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

Auto Center Punch

PUN-430.00

- PUN-430.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $8.97

- Gold Club Price: $6.73

Optional Tools

DELUXE 4 HOLE METAL PUNCH

PUN-420.04

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $64.95

- Gold Club Price: $48.71

Euro Corner Punch Plier 1.50mm

PLR-133.80

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $22.95

- Gold Club Price: $17.21

- Category: Metalwork

- Technique(s): Drilling

Making Bead Link Chain

Making Bead Link Chain

Acculoop Precision Pliers Ear Wires

Acculoop Precision Pliers Ear Wires

Using Mandrels for Making Jump Rings

Using Mandrels for Making Jump Rings

Jump Ring Tips

Jump Ring Tips

Working with Annealed Steel Wire

Working with Annealed Steel Wire

Patina Tips and Tricks for Copper

Patina Tips and Tricks for Copper

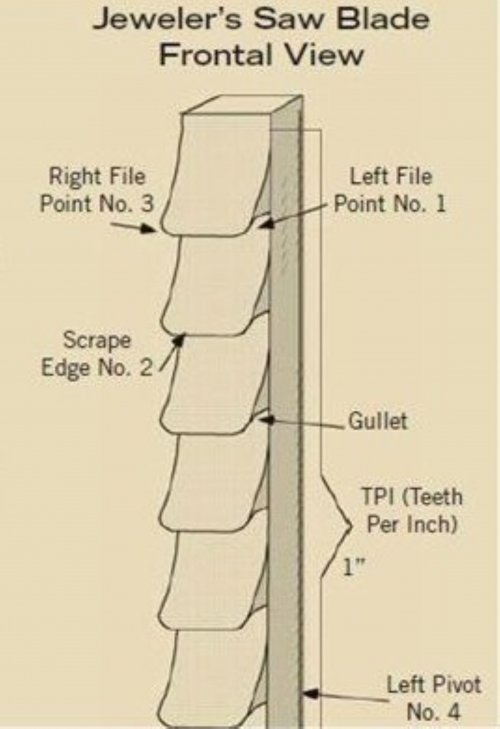

Sawing and Filing Safety Tips

Sawing and Filing Safety Tips

Creating on the Go

Creating on the Go

Riveting Tips

Riveting Tips

Texture Summer School

Texture Summer School

Reproducing Designs

Reproducing Designs

Up Your Design Game with Flat Wire

Up Your Design Game with Flat Wire

Sawing Tiny Shapes

Sawing Tiny Shapes

Quick Ring Shank Sizing

Quick Ring Shank Sizing

Stabilizing a Large Hole Bead

Stabilizing a Large Hole Bead

Protect Your Sharp Tools and Your Fingers

Protect Your Sharp Tools and Your Fingers

Tiny Chain Link Fix

Tiny Chain Link Fix

Organized Storage for Wire

Organized Storage for Wire

Taking Risks

Taking Risks

Jump Ring Rescue

Jump Ring Rescue

Centering Your Stamp Patterns

Centering Your Stamp Patterns

Stamping Tips for Success

Stamping Tips for Success

Finding My Place, a Bangle Tip

Finding My Place, a Bangle Tip

No Time for Pickling

No Time for Pickling

Eye Pin Dilemma

Eye Pin Dilemma

It's a Fit Issue

It's a Fit Issue

Flux Fix

Flux Fix

Using Templates in Jewelry Making

Using Templates in Jewelry Making

Chain Maintenance

Chain Maintenance

Bracing For It

Bracing For It

A Weighty Matter

A Weighty Matter

Altering an Existing Chain - From Paperclip to Petal Links

Altering an Existing Chain - From Paperclip to Petal Links

Essential Sawing Tips

Essential Sawing Tips

Choosing the Right Saw Blade Part 1

Choosing the Right Saw Blade Part 1

Choosing the Right Saw Blade Part 2

Choosing the Right Saw Blade Part 2

Wire Guard Tip

Wire Guard Tip

Getting the Ring Shank Size Right

Getting the Ring Shank Size Right

Heat Rivet Repair

Heat Rivet Repair

Making It Work

Making It Work

Consistent Earwire Pairs

Consistent Earwire Pairs

Ear Wires on the Fly

Ear Wires on the Fly

Production Mode

Production Mode

Sputtering Torch

Sputtering Torch

Nylon Hammer Remodel

Nylon Hammer Remodel

Saved by Scotch Tape

Saved by Scotch Tape

Pro Polish Pad

Pro Polish Pad

Labels Make the World Go Around

Labels Make the World Go Around

I Spy a Bit

I Spy a Bit

The Magic of Double Stick Tape

The Magic of Double Stick Tape