Closed Jump Rings Soldering vs Fusing

In jewelry making, there's rarely just one "right" way to do things, which is why staying open to new tools and techniques is so valuable. In the final part of this four part series, Judy Larson shares methods for turning open jump rings into closed ones, along with practical advice on soldering, tools, and tips for keeping your workflow efficient. It's an insightful look at how preparation and practice can make your designs more seamless.

Jump to Each Lesson in the Jump Ring Series

#1 Coiling Wire for Jump Rings #2 Cutting Coil into Jump Rings #3 Opening & Closing Jump Rings #4 Closed Jump Rings Soldering vs Fusing

Jump to Each Lesson in the Jump Ring Series

Instructions

The following steps explain different ways to turn open jump rings into closed jump rings, along with my reasoning for when each method is useful.

Soldering Trifecta with Kim St. Jean is an excellent class full of tips and tricks that help you achieve professional results with different solders and techniques.

To find the method that works best for your tools and skills, practice each technique before moving into full production.

Soldering Trifecta with Kim St. Jean is an excellent class full of tips and tricks that help you achieve professional results with different solders and techniques.

To find the method that works best for your tools and skills, practice each technique before moving into full production.

Note: You may not need closed jump rings often, but when you do, it can feel like a hassle to bring out all the soldering equipment for just one ring.

Once you know which size and gauge you use most often, it's smart to make several of those in advance.

That way, you'll always have the right closed rings on hand when you need them.

Once you know which size and gauge you use most often, it's smart to make several of those in advance.

That way, you'll always have the right closed rings on hand when you need them.

Making Closed Rings

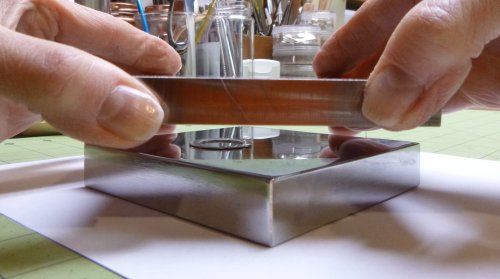

For good seam joins, the rings must be clean. If they've been sitting out for several months, give them a quick cleaning in a silver dip. Rinse and dry them thoroughly before working.

The rings must also be tightly closed, with both ends flush and even.

No light should show between the ends of the jump ring. If there is any light, the join can easily fail.

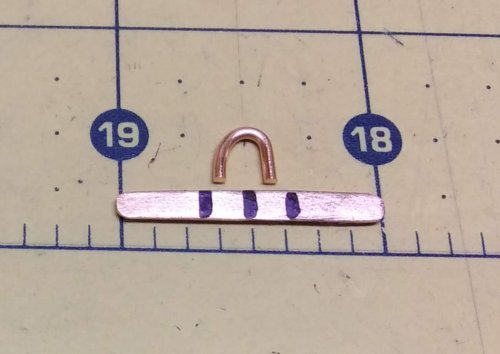

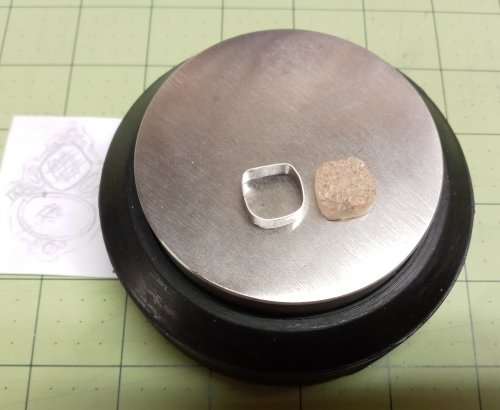

The example shown uses 16-gauge Argentium wire. The top row displays finished rings, while the bottom row shows the method.

Use a smaller amount of paste solder and a smaller chip of solder than pictured. The photo uses extra solder only for visibility.

Use half the amount shown. The less solder you use, the less clean-up will be needed around the seam.

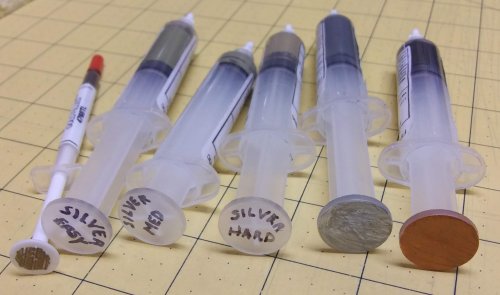

In the image shown are jump rings made in different formats, from left to right:

The rings must also be tightly closed, with both ends flush and even.

No light should show between the ends of the jump ring. If there is any light, the join can easily fail.

The example shown uses 16-gauge Argentium wire. The top row displays finished rings, while the bottom row shows the method.

Use a smaller amount of paste solder and a smaller chip of solder than pictured. The photo uses extra solder only for visibility.

Use half the amount shown. The less solder you use, the less clean-up will be needed around the seam.

In the image shown are jump rings made in different formats, from left to right:

| Fusing | Medium paste solder | Medium chip/sheet solder |

Soldering:

If you are using gold filled, sterling, or base metal wire, solder must be applied.When working with paste solder, there is no need to add flux since it is already included in the formula. With traditional wire and chip solders, flux is required or the solder will not flow. Without flux, solder may melt but only ball up instead of spreading.

Argentium and fine silver do not develop fire scale when torch heated, so flux is not necessary. However, flux can still be useful as an indicator. Once it turns clear and glassy, solder flow is close.

Sterling silver embellishments and findings should be fluxed to protect them. Even when using paste solder on sterling silver rings, I still fluxed them to avoid dealing with fire scale.

When soldering, paste and chip solder behave similarly. Place the solder beneath the jump ring seam on the soldering surface. Since solder follows heat, torching the ring will cause it to liquefy and flow up into the seam.

When you see the silver flash on top of the jump ring, remove the heat immediately. The ring is closed.

After cooling, check the seam and refine if needed.

Fusing:

Argentium and fine silver jump rings is simple, but like any new skill, practice makes perfect.As with soldering, the rings must be tightly closed, with both ends flush and even. No light should show between them. If there is any gap, the join can fail.

One drawback of fusing is that it does not always create the strongest join. In my experience, solder joins are often stronger than fused ones.

So why use fusing at all? The biggest advantage is no solder clean-up.

Another benefit is when making chains that must be pulled through a drawplate, such as foxtail or loop-in-loop chains. These chains need to be annealed before the first draw and again during the drawing process. If each link were soldered, it would be too easy to overheat a section, causing the solder to flow and fuse multiple rings together. This would leave an unbendable section of chain.

Fusing Rings:

To fuse rings, use a Butane Torch Head attached to a butane canister for larger rings. For smaller rings, a Jumbo Max Flame Butane Torch works well. Keep rings spaced out on a soldering surface and work on one at a time. Place each ring with the seam facing away from you so you know exactly where to watch.Move the flame around the ring and carefully heat it. The surface will go from shiny, to dull, to frosty, then back to very shiny and slightly molten. Use a heat-and-pull-back rhythm until the seam begins to fuse. Once the seam starts to fill in, immediately remove the heat. The seam will finish fusing as the ring cools. Repeat for each ring.

Let the rings cool on the soldering surface, then flip them over. If the seam isn't fully fused, repeat the process on the other side.

Do not quench too soon after fusing, as the join may crack. Allow the rings to cool for 20-30 seconds, then dump them into a metal bowl set on a bench block to finish cooling.

If a seam wasn't tightly closed, let the ring cool, flip it, and reheat just that area to fuse it. If the ends ball up instead, continue to ball the wire. You'll have a perfect embellishment to use in another project.

Fusing many jump rings can be repetitive, and it's easy to let your mind wander. If a ring overheats, it may shrink in size. Save those smaller rings for the beginning or end of a chain, or repurpose them in other designs.

Base Metals:

I mainly work with silver, but I also have tips for soldering copper and other base metal rings.This coil of copper solder already contains flux, so you don't need to spray or paint flux onto the soldered areas. Adding flux to the entire piece will still help prevent fire scale.

One drawback is that joins made with this solder are very brittle. If the seam is hammered, bent, or stressed, it will likely fail.

A seam that won't be stressed after soldering will hold up fine.

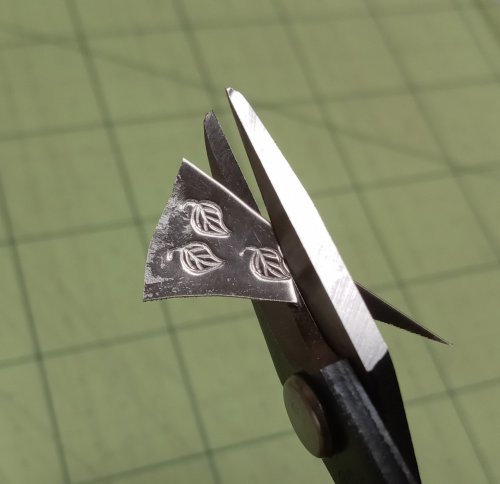

Always clean the solder wire before use. Since round wire tends to roll, it helps to hammer the end flat before cutting off small pieces. This keeps the solder in place instead of rolling around.

Another drawback: even though the coil looks copper-colored, the finished join will show a definite silver cast.

Using Paste Solder:

I prefer using paste solder formulated for base metals, since it includes flux and works well for soldering. I'll even use it for pick soldering. To avoid confusion, I paint the tops with copper and brass or bronze colors so I can tell them apart from the silver paste solders in the same container.The drawback is that, like copper wire solder, it doesn't create an invisible seam. The overflow is harder to clean up compared to paste, wire, or sheet solders for silver.

Base metal wire and paste solders come in only one flow temperature. This makes layering more challenging, though not impossible.

They also don't take patina as well as silver solders, which makes it harder to cover or disguise solder overflows that can't be removed.

Making Consistent Large Size Closed Rings

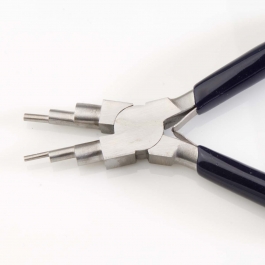

Sometimes coiling wire to make consistently sized large rings, meant to be soldered or fused closed, does not work well even with specialty pliers.

In that case, coil several rings at the desired size, then cut them apart.

Open each ring, straighten the wire, measure the shortest piece, and cut the rest of the wires to match that length.

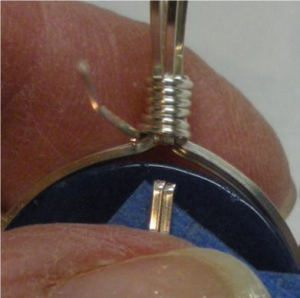

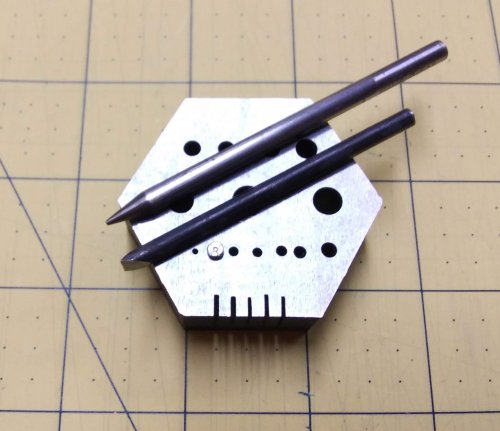

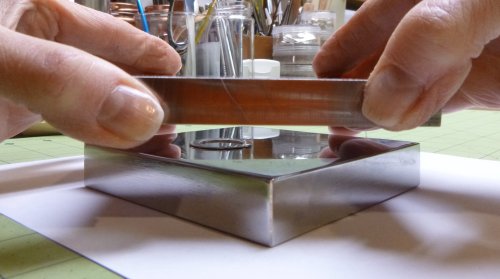

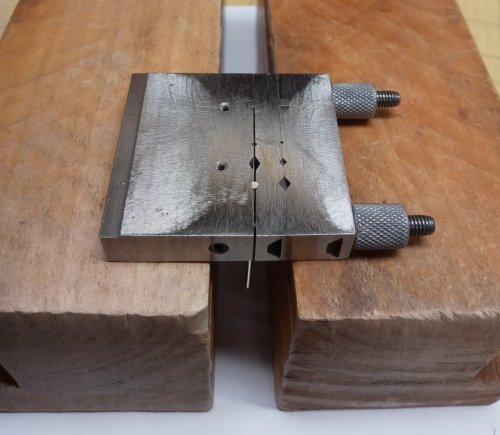

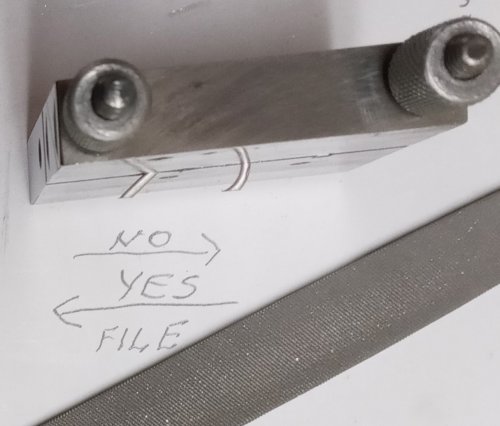

Miter Joint Jig Vise:

File both ends of each wire flat, making sure they are all the same length. The ends must be perfectly flat for a proper solder join.

Ideally, use a Miter Joint Jig Vise. Secure one end of the wire in the larger diamond-shaped opening so the cut marks can be removed. File the end flat and flush with the vise surface.

Repeat the process with the other end of the wire.

Repeat the process with the other end of the wire.

Note: The vise shown here is designed for 45 and 90 degree angles. Use the flat 90 degree portion.

If you don't have a Miter Joint Jig Vise, you can use flat nose pliers instead.

Place the wire as close as possible to the fulcrum of the pliers. This area creates a 90-degree angle that lets you file the wire end flat.

Positioning the wire here also reduces the pressure needed to grip the handles, lowering the chance of marring the wire.

Hint: Wrap electrician's tape around the plier jaws to help protect the wire from marks.

Rest the end of the plier jaws on the edge of your work surface, then file the wire flat and flush with the top of the pliers.

Place the wire as close as possible to the fulcrum of the pliers. This area creates a 90-degree angle that lets you file the wire end flat.

Positioning the wire here also reduces the pressure needed to grip the handles, lowering the chance of marring the wire.

Hint: Wrap electrician's tape around the plier jaws to help protect the wire from marks.

Rest the end of the plier jaws on the edge of your work surface, then file the wire flat and flush with the top of the pliers.

Shape the wire lengths into oval or "D" shapes, matching the ends as closely as possible.

No light should be visible between the wire ends from any angle.

Form the wire into a "smile," then pull the ends back together to create a flush connection.

If using square wire, ensure the corners align precisely.

No light should be visible between the wire ends from any angle.

Form the wire into a "smile," then pull the ends back together to create a flush connection.

If using square wire, ensure the corners align precisely.

Solder or fuse the seam closed.

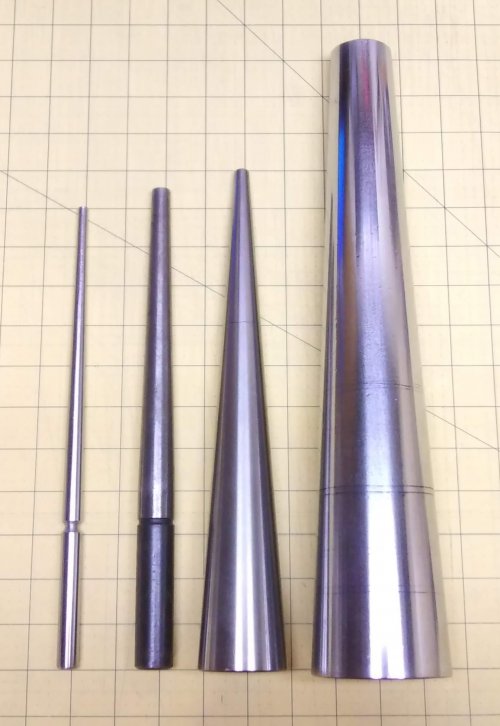

Shape the large ring on a ring or hoop mandrel.

Make Lists and Charts

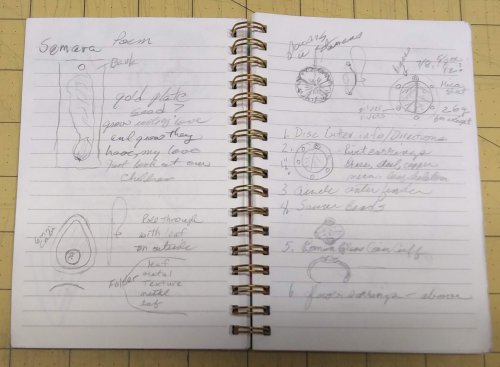

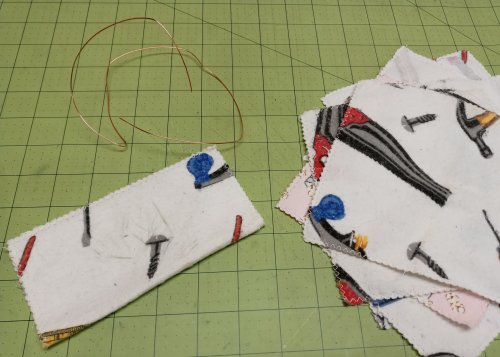

I don't like to figure things out over and over, so I take plenty of notes, photos, and make lists and charts to reference often.

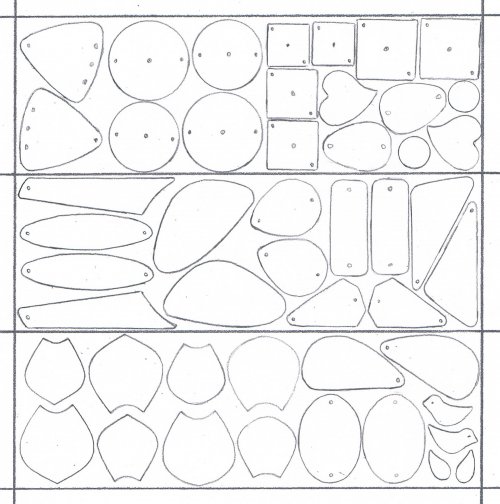

You may find the following two charts from Mix "O" Match Earrings helpful, especially when making larger rings.

Wire lengths in relation to plier barrels: Wire, especially half hard, is springy and creates coils slightly larger than the barrel size after wrapping.

I made a list of approximate wire lengths needed to wrap around the barrel of three different 3-step pliers. I also added extra length to account for trimming with flush cutters and filing the ends.

You may find the following two charts from Mix "O" Match Earrings helpful, especially when making larger rings.

Wire lengths in relation to plier barrels: Wire, especially half hard, is springy and creates coils slightly larger than the barrel size after wrapping.

I made a list of approximate wire lengths needed to wrap around the barrel of three different 3-step pliers. I also added extra length to account for trimming with flush cutters and filing the ends.

Wire Length Reference Chart by Pliers

| Pliers | 3 Step Wire Wrapping Flat Nose | Small Barrel Wrap 'N' Tap | Large Barrel Wrap 'N' Tap | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Step | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| 18 Gauge Wire | n/a | 3/4" | 13/16" | 5/8" | 1 1/4" | n/a | n/a | n/a | n/a |

| 16 Gauge Wire | n/a | n/a | n/a | 5/8" | 1 1/4" | 1-11/16" | 2" | 2 1/2" | 3" |

| 14 Gauge Wire | n/a | n/a | n/a | n/a | 1 1/4" | 1-11/16" | 2" | 2 1/2" | 3" |

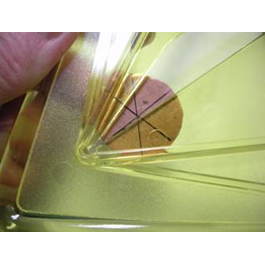

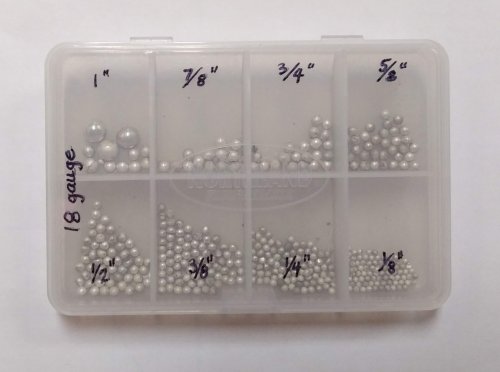

Visual comparison of ring gauges and sizes:

It is helpful to me to keep photographic size references.The approximate inside diameters of the ripple rings on the left are as follows:

Materials

Wire - Wide variety of gauges, tempers and metals

Wide variety of Sterling Silver Jump Rings

Copper Solder Paste, 1/2 ozt, Soft

SOL-824.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $9.95

- Gold Club Price: $7.46

Silver Solder Paste Hard SS75 - 1/4 T.O.

SOL-822.20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $19.95

- Gold Club Price: $14.96

Silver Solder Paste Soft SS65- 1/4 T.O.

SOL-822.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.95

- Gold Club Price: $12.71

Silver Solder Paste Medium SS70 - 1/4 T.O.

SOL-822.15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

Sheet Solder Variety Pack

SOL-860.90

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.95

- Gold Club Price: $12.71

Silver Solder Wire Variety Pack, 6 Inches Each of Soft, Medium and Hard

SOL-VAR-3PK

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $9.95

- Gold Club Price: $7.46

Tools

Deluxe Soldering Kit

G15-5

- G15-5

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $116.97

- Gold Club Price: $87.73

Soldering Trifecta with Kim St. Jean

STC-TRIFECTA

- STC-TRIFECTA

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $197.00

- Gold Club Price: $147.75

Heavy Duty Wire Shear

PLR-460.00

- PLR-460.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $44.95

- Gold Club Price: $33.71

Lindstrom Multi-Purpose Shear, 5-3/4 Inches

G2-6000

- G2-6000

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $39.95

- Gold Club Price: $29.96

Multi-Size Wrap 'N' Tap Pliers, Large Barrels

PLR-746.03

- PLR-746.03

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

WireJewelry - Ultimate Wire-Pliers Jewelry Pliers with Case, Set of 5

G15-20

- G15-20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $170.72

- Gold Club Price: $128.04

Multi Angle Cutting Jig

VIS-512.00

- VIS-512.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $84.95

- Gold Club Price: $63.71

6 Piece Assorted File Set with Wooden Handle

G14-7

- G14-7

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $5.57

- Gold Club Price: $4.18

Stainless Steel Ring Mandrel Sizes 1-15

G7-2

- G7-2

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $32.95

- Gold Club Price: $24.71

5/8 Inch Double Rubber/Nylon Head Hammer - Pack of 1

G3-26

- G3-26

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $4.97

- Gold Club Price: $3.73

3 Step Wire Wrapping Pliers - Pack of 1

G2-19

- G2-19

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.95

- Gold Club Price: $10.46

Multi-Size Wrap 'N' Tap Pliers, Small Barrels

PLR-746.02

- PLR-746.02

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

Optional Tools

Soldering Trifecta with Kim St. Jean DVD Set

DVD-TRIFECTA

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $197.00

- Gold Club Price: $147.75

- Category: General Education

- Technique(s): Making Jump Rings

Cleaning Your Jewelry

Cleaning Your Jewelry

Build A Tool Rack

Build A Tool Rack

Clamps for Jewelry Making

Clamps for Jewelry Making

Finishing Wire Ends

Finishing Wire Ends

Handmade Closures

Handmade Closures

Removing Tarnish From Your Jewelry

Removing Tarnish From Your Jewelry

Homemade Pickle

Homemade Pickle

Wire Wrapped Loops

Wire Wrapped Loops

How to Make Balled Head Pins

How to Make Balled Head Pins

Lessen the Noise - Save Your Eardrums

Lessen the Noise - Save Your Eardrums

Make a Rivet and Eyelet Tile

Make a Rivet and Eyelet Tile

Two Tips for Making Pendant Bails with Craft Wire

Two Tips for Making Pendant Bails with Craft Wire

Petal Forming on a Wood Block

Petal Forming on a Wood Block

Save Your Fingers while Texturing

Save Your Fingers while Texturing

Soldering on Copper

Soldering on Copper

Sticker Templates

Sticker Templates

Using 6 Step Barrel Pliers

Using 6 Step Barrel Pliers

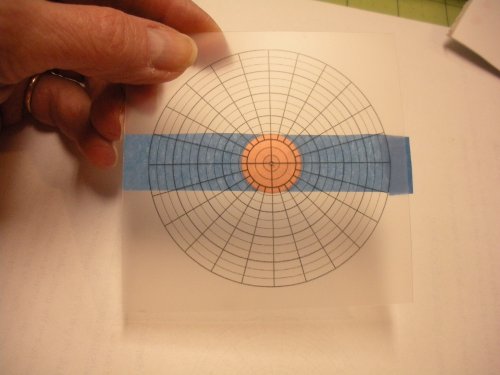

Using a Center Finder

Using a Center Finder

Using a Tile to Cut Rivets

Using a Tile to Cut Rivets

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Household Super Glue on Minor Cuts, Nicks and Scrapes

Using Tiles on Tube Rivets and Eyelets

Using Tiles on Tube Rivets and Eyelets

Clothespin Tools

Clothespin Tools

Making Decorative Granulation Beads

Making Decorative Granulation Beads

Using Your Hole Punch Pliers

Using Your Hole Punch Pliers

Decorative Granulation and Beads

Decorative Granulation and Beads

How to Find and Mark the Center of a Disc.

How to Find and Mark the Center of a Disc.

Choosing the Right Clasp

Choosing the Right Clasp

Chunky Chain Inspiration

Chunky Chain Inspiration

Tool Tip - Steampunk or Industrial Rivets

Tool Tip - Steampunk or Industrial Rivets

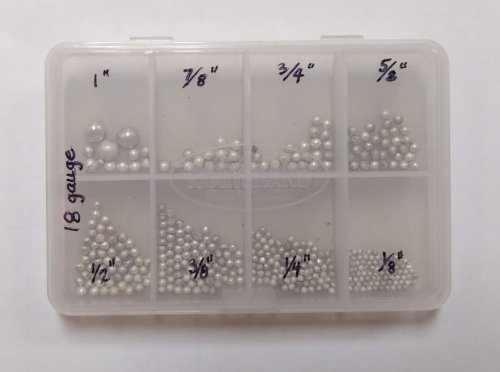

Storing Jump Rings

Storing Jump Rings

Wear Your Brooches on a Neckwire

Wear Your Brooches on a Neckwire

Storing Your Metal

Storing Your Metal

Using Disc Cutter Shims

Using Disc Cutter Shims

Conditioning a Rawhide Mallet

Conditioning a Rawhide Mallet

Flattening Metal Pieces

Flattening Metal Pieces

Quenching

Quenching

Saving a Broken Solder Brick

Saving a Broken Solder Brick

Why I Use Solder Paste

Why I Use Solder Paste

Designing a Toggle Clasp That Works

Designing a Toggle Clasp That Works

Round Mandrels

Round Mandrels

Get the Look of Eyelets

Get the Look of Eyelets

Earring Pairs Template

Earring Pairs Template

Storing and Caring for Files

Storing and Caring for Files

Open or Closed Jump RIngs on Bracelets and Necklaces

Open or Closed Jump RIngs on Bracelets and Necklaces

Versatile Permanent Markers

Versatile Permanent Markers

You Used What

You Used What

Rescuing a Very Used Magnesia Soldering Block

Rescuing a Very Used Magnesia Soldering Block

Using Hole Punch Pliers

Using Hole Punch Pliers

Metal Shears Care

Metal Shears Care

Paperclip Earrings

Paperclip Earrings

Think Outside the Box - Alternative Metal Texturing

Think Outside the Box - Alternative Metal Texturing

Make Stamping Metal a Bit Easier

Make Stamping Metal a Bit Easier

Stone Bezel Setting Tips

Stone Bezel Setting Tips

Viking Knit Tips

Viking Knit Tips

Using Glue Under Cabochons

Using Glue Under Cabochons

Tool Tip - Digital Pocket Scale

Tool Tip - Digital Pocket Scale

Repeat Performance

Repeat Performance

Another Way to Condition a Rawhide Mallet

Another Way to Condition a Rawhide Mallet

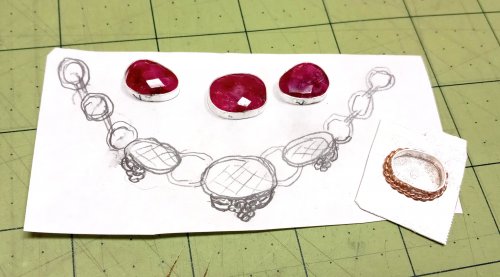

Carry a Sketch Pad

Carry a Sketch Pad

Why You Should Take a Class

Why You Should Take a Class

Jewelry Making Templates

Jewelry Making Templates

Carry a Sketch Pad

Carry a Sketch Pad

Keeping Your Bracelet Focals in Place

Keeping Your Bracelet Focals in Place

Metal Content Stamping

Metal Content Stamping

Using Sanding Sponges and Papers

Using Sanding Sponges and Papers

Adding Depth to Carved Beads and Cabochons

Adding Depth to Carved Beads and Cabochons

Closing Rings Tightly for Soldering

Closing Rings Tightly for Soldering

Squaring Wire Ends

Squaring Wire Ends

Ring Mandrels

Ring Mandrels

Tool Tip - Bench Brushes

Tool Tip - Bench Brushes

Scrap Wire Twisted Rings

Scrap Wire Twisted Rings

Tool Tip - Soft Bristle Metal Brushes

Tool Tip - Soft Bristle Metal Brushes

Project Multiples - Calibrated Cabochons

Project Multiples - Calibrated Cabochons

Mobius Pearl Drop Earrings

Mobius Pearl Drop Earrings

Copper Wire Solder

Copper Wire Solder

Large Dapping Punches and Alternatives

Large Dapping Punches and Alternatives

Project Multiples - Glass Pebble Cabs

Project Multiples - Glass Pebble Cabs

Project Storage

Project Storage

Tiny Bead and Findings Storage

Tiny Bead and Findings Storage

Working Smart

Working Smart

Display Trays as Storage

Display Trays as Storage

Making TIny Leaves

Making TIny Leaves

Adapting a Tutorial

Adapting a Tutorial

Build Better Bead Storage

Build Better Bead Storage

Using Magical Crimping Pliers

Using Magical Crimping Pliers

Add a Touch of Gold

Add a Touch of Gold

Make a Lacy Argentium Scrap Metal Sheet

Make a Lacy Argentium Scrap Metal Sheet

Birch Bark Texture

Birch Bark Texture

Versatile Snap-on Bails

Versatile Snap-on Bails

Bead Cap Primer

Bead Cap Primer

Using Glue Sticks with Printed Templates

Using Glue Sticks with Printed Templates

Choosing a Lake or Riverstone

Choosing a Lake or Riverstone

Do a Facebook Collaboration

Do a Facebook Collaboration

Shielding a Jewelry Piece When Stone Setting

Shielding a Jewelry Piece When Stone Setting

Some Ideas Are Right in Front of You

Some Ideas Are Right in Front of You

Curving and Scrolling Wire

Curving and Scrolling Wire

Using Snapsets to Add Sparkle to Your Work

Using Snapsets to Add Sparkle to Your Work

Cutting Wire Multiples of the Same Length

Cutting Wire Multiples of the Same Length

Separating Distinct Textures on a Single Piece of Metal

Separating Distinct Textures on a Single Piece of Metal

Changing the Size of a Pearl

Changing the Size of a Pearl

Easy Ring Cleaning

Easy Ring Cleaning

Add a Bit of Dimension

Add a Bit of Dimension

Keeping Projects Separate

Keeping Projects Separate

Tumbling and Polishing Metal Beads

Tumbling and Polishing Metal Beads

Unexpected Jewels

Unexpected Jewels

Saws and Turning Radius

Saws and Turning Radius

Flattening Metal Pieces

Flattening Metal Pieces

Mobius Ring Spacers

Mobius Ring Spacers

Filing Angled Wires in a Jig

Filing Angled Wires in a Jig

Storing Handmade Elements

Storing Handmade Elements

Simple Way to Straighten Wire

Simple Way to Straighten Wire

Two Ways to Make Simple Loops

Two Ways to Make Simple Loops

Making Simple Eyepins

Making Simple Eyepins

Using Fun Tak as a Resist

Using Fun Tak as a Resist

Why Use a Binder to Store Embellishments

Why Use a Binder to Store Embellishments

Storing Dapping Blocks and Punches

Storing Dapping Blocks and Punches

Wire Basics - Opening and Closing Jump Rings

Wire Basics - Opening and Closing Jump Rings

Enlarging a Bezel

Enlarging a Bezel

Leaf Inspirations

Leaf Inspirations

Earring Findings for Different Ages

Earring Findings for Different Ages

Accidentally Learning Something New

Accidentally Learning Something New

Fusing Jump Rings

Fusing Jump Rings

Tool Tip - Divided Caliper Scribe

Tool Tip - Divided Caliper Scribe

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Out of the Mouths of Babes or Fixing a Spinning Bracelet

Rethinking a Design

Rethinking a Design

When Bead Holes are Too Large

When Bead Holes are Too Large

Soldering a Dome to a Backplate

Soldering a Dome to a Backplate

Eye of Shiva AKA Pacific Cat's Eye

Eye of Shiva AKA Pacific Cat's Eye

Ribbon Wrapped Bracelet tips

Ribbon Wrapped Bracelet tips

Making Lightweight Earrings with Unexpected Finds

Making Lightweight Earrings with Unexpected Finds

Tool Tip - Indispensable Tapes

Tool Tip - Indispensable Tapes

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

What Happens To Pearls Not Worn, Cleaned, and Stored Properly

Aha Lightbulb Moment

Aha Lightbulb Moment

Adding Loops for Dangles on a Classic Wire Bezel Wrap

Adding Loops for Dangles on a Classic Wire Bezel Wrap

After the Rain - Found Treasures

After the Rain - Found Treasures

Back to School

Back to School

Bezel Solution for Corners and Points

Bezel Solution for Corners and Points

Filling Holes in Stones

Filling Holes in Stones

Dots to the Rescue

Dots to the Rescue

Raising Stones in Bezel Settings

Raising Stones in Bezel Settings

Leveling the Bottom of a Large Bezel

Leveling the Bottom of a Large Bezel

Using Leftovers

Using Leftovers

Make-do Sawing Solutions

Make-do Sawing Solutions

Combining Tutorials

Combining Tutorials

Scrap Melt

Scrap Melt

What's Your Jewelry Style

What's Your Jewelry Style

Using Wax from Braces

Using Wax from Braces

Sometimes Simple Really is Better

Sometimes Simple Really is Better

Bead Soup and Small Changes

Bead Soup and Small Changes

Repurposing Sterling Cord End Findings

Repurposing Sterling Cord End Findings

Wire Wrapped Bail Finishing Options

Wire Wrapped Bail Finishing Options

Protecting The Back of a Piece When Setting Stones

Protecting The Back of a Piece When Setting Stones

Altering Your Dapping Block

Altering Your Dapping Block

Trimming Around a Bezel

Trimming Around a Bezel

Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves

Labeling Cabs When Working with Them

Labeling Cabs When Working with Them

Basic Round Well Wood Dapping Blocks

Basic Round Well Wood Dapping Blocks

Get Inspired by What's on Your Bench

Get Inspired by What's on Your Bench

When Things Go Awry

When Things Go Awry

Putting On and Taking Off a Cuff Bracelet

Putting On and Taking Off a Cuff Bracelet

Adding Hearts to Your Designs

Adding Hearts to Your Designs

Taking Care of Your Rolling Mill

Taking Care of Your Rolling Mill

Power Up

Power Up

Hammer Basics

Hammer Basics

Wire Temper and Jump Rings

Wire Temper and Jump Rings

Embellish Bezels with Twisted Wire

Embellish Bezels with Twisted Wire

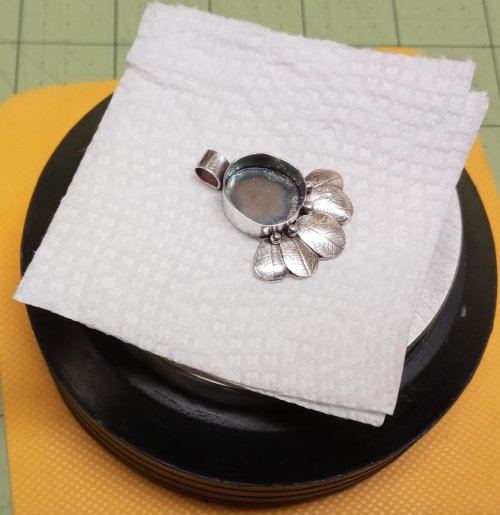

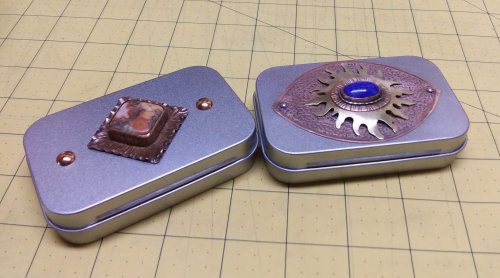

Embellish a Treasure Box

Embellish a Treasure Box

Make a Polymer Clay Cabochon Mandrel

Make a Polymer Clay Cabochon Mandrel

Jewelry Packaging for Small Items - Pillow Boxes

Jewelry Packaging for Small Items - Pillow Boxes

Make-do Sawing Solutions

Make-do Sawing Solutions

Ball Chain Embellishments

Ball Chain Embellishments

Pickling and Super Pickle

Pickling and Super Pickle

A Better T-bar

A Better T-bar

A Better Way to Change a Saw Blade

A Better Way to Change a Saw Blade

Making Consistent Hanging Loops

Making Consistent Hanging Loops

Targeted Patina

Targeted Patina

Coin Focal Inspiration

Coin Focal Inspiration

Bracelet and Paperclip Trick

Bracelet and Paperclip Trick

What Wire is Best for Earring Findings

What Wire is Best for Earring Findings

Storing Your Metal Stamps

Storing Your Metal Stamps

Save Those Old Buttons

Save Those Old Buttons

Adjusting Purchased Ear Wires

Adjusting Purchased Ear Wires

Twisted Wire Tips

Twisted Wire Tips

Stash Inspiration and Notes

Stash Inspiration and Notes

Short Quotes for Stamped Jewelry

Short Quotes for Stamped Jewelry

My Favorite Tweezers

My Favorite Tweezers

No Rolling Mill- No Problem

No Rolling Mill- No Problem

Coiling Wire for Jump Rings

Coiling Wire for Jump Rings

Cutting Coils Into Jump Rings

Cutting Coils Into Jump Rings

Recycling Scrap Into Sheet Metal

Recycling Scrap Into Sheet Metal