Basic Bezel Wire Tutorial

- Category: Metalwork

- Technique(s): Butane Torch Techniques

- Skill Level: Beginner

We all learn different skills in different ways and apply that knowledge in ways that someone else might not or might not think of. There are no set RULES for making bezels, only what works best for you. So, watch a few videos, read a few books, take notes, and apply the parts learned that will work best in your situation with the tools and supplies you are working with.

Basic plain strip bezel wire is available in a variety of metals, thicknesses, and widths. Wirejewelry.com carries copper bezel wire in 26 gauge as well as 32 gauge. They also carry 28 Gauge 3/16" Fine Silver Bezel Wire in 1, 5, and 10 foot lengths. If you will be making a lot of precious metal bezel-set stone jewelry, longer lengths of bezel wire are usually more cost effective.

Basic plain strip bezel wire is available in a variety of metals, thicknesses, and widths. Wirejewelry.com carries copper bezel wire in 26 gauge as well as 32 gauge. They also carry 28 Gauge 3/16" Fine Silver Bezel Wire in 1, 5, and 10 foot lengths. If you will be making a lot of precious metal bezel-set stone jewelry, longer lengths of bezel wire are usually more cost effective.

Materials

28 Gauge 3/16" Fine Silver Bezel Wire

H9-28BZL

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $13.60

- Gold Club Price: $10.20

32 Gauge Copper Bezel Wire - 10FT

H30-11A

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $6.40

- Gold Club Price: $4.80

32 Gauge Red Brass Bezel Wire - 10FT

H30-3A

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $7.70

- Gold Club Price: $5.78

22 Gauge Dead Soft Fine Silver Sheet - 6 Inches

H9-22SM6

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1 Inch

- Price: $64.86

- Gold Club Price: $48.65

Tools

Bezel Roller Deluxe

PSH-776.00

- PSH-776.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $3.98

- Gold Club Price: $2.98

Curved Burnisher with Wooden Handle

G8-14

- G8-14

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $3.57

- Gold Club Price: $2.68

WET/DRY PAPER 9 X 11 ASST- 20PC- 2EA GRIT 180-3000

ABR-500.90

- ABR-500.90

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

Instructions

Step 1:

How wide should bezel wire be?

It is helpful to think of a cabochon or stone in terms used to describe a cut gemstone.

The easiest cabochon to bezel set when first starting is one without a lot of angles, corners, and curves. Round and oval cabochons are good. Cabochons can be thick or thin-first photo. They do not always have to be gemstones. Glass pebbles-second photo-can be made into a beautiful piece of jewelry.

These have one thing in common. It is easy to find where the stones start to curve in above the girdle. The bezel should be at least 1mm to 1.5mm higher than that point. The larger the stone, the wider/higher the bezel may need to be to hold it in place. Half a millimeter can make a huge difference in how much of a stone top is covered with a finished bezel as well as how it looks.

The crackle fire agate on the left in the first photo needs a wider bezel than the amazonite cabochon to the right. If the same height bezel wire used on the crackle fire agate was used on the amazonite, it would be very difficult to push the top edge of the bezel in smoothly without kinks or overlaps around the edge. After bezel setting a few stones, you will get a feel for the width of bezel needed for cabochons.

These have one thing in common. It is easy to find where the stones start to curve in above the girdle. The bezel should be at least 1mm to 1.5mm higher than that point. The larger the stone, the wider/higher the bezel may need to be to hold it in place. Half a millimeter can make a huge difference in how much of a stone top is covered with a finished bezel as well as how it looks.

The crackle fire agate on the left in the first photo needs a wider bezel than the amazonite cabochon to the right. If the same height bezel wire used on the crackle fire agate was used on the amazonite, it would be very difficult to push the top edge of the bezel in smoothly without kinks or overlaps around the edge. After bezel setting a few stones, you will get a feel for the width of bezel needed for cabochons.

Since I live by a lake and collect stones to set, I am using a sketch of them to describe where to measure for bezel width. The bezel wire must be wide enough to cover the girdle-the dotted line on the stones-and to cover a bit of the crown-the crown and table by a millimeter or more.

The arrows on the rocks show how high the bezel wire must at least be to capture the stone. In most cases, the height of the girdle around the rock will not be the same. Most of the time this will not be a problem, as in the first rock. If one end of the rock is too thin, it can be raised in the bezel with a small shim of metal soldered to the backplate.

The arrows on the rocks show how high the bezel wire must at least be to capture the stone. In most cases, the height of the girdle around the rock will not be the same. Most of the time this will not be a problem, as in the first rock. If one end of the rock is too thin, it can be raised in the bezel with a small shim of metal soldered to the backplate.

The girdle on both ends of this rock are the same height. Viewing from another angle, the girdles on each side of the rock are much higher than the girdle on either ends. The bezel wire needs to be wider to accommodate the side girdle height, the higher of the two.

With rocks, after the bezel wire is pushed in around the stone, it is not usually a problem if the width of bezel pushed in is uneven around the stone, but some people may find it visually displeasing. When first starting out, try to steer clear of uneven cabochons and stones. If you really want to try your hand at something like uneven height stones, practice with 26 gauge copper bezel wire before working up to silver.

With rocks, after the bezel wire is pushed in around the stone, it is not usually a problem if the width of bezel pushed in is uneven around the stone, but some people may find it visually displeasing. When first starting out, try to steer clear of uneven cabochons and stones. If you really want to try your hand at something like uneven height stones, practice with 26 gauge copper bezel wire before working up to silver.

In most cases, glue is not used when bezel setting cabochons, but stones are another matter. Leveling stones is not new. Stones, nuggets and thin cabochons in early turquoise jewelry were set with cushions of sawdust, ground corncobs, and sometimes cardboard shims, under them which degraded over time. So long as whatever is used to shim or raise a stone is not biodegradable, it is fine to use. E6000 has only been around for a bit over 30 years, so we don't really know. A more stable alts lifespan. An alternative would be two-part epoxy. Most of the time a bit of wire shim soldered to the backplate is all that is needed to level or raise a stone. See Step 15 for a method using wire.

Step 2

Longer lengths can be unwieldly to work with, especially if you like to form bezels around stones on a raised surface such as a bench block. Enter painter's tape.

After purchasing a better painter's tape for painting, I started using my old tape with jewelry. Since one inch was too wide for most of my needs, I used a retractable blade cutter to cut into the roll 5/16" in from one edge all the way around. Since I did not cut all the way to the cardboard roll core, every now and then the cut needs to be made deeper. The narrow strip can be used to "measure" the length of bezel wire needed around the perimeter of a stone.

After purchasing a better painter's tape for painting, I started using my old tape with jewelry. Since one inch was too wide for most of my needs, I used a retractable blade cutter to cut into the roll 5/16" in from one edge all the way around. Since I did not cut all the way to the cardboard roll core, every now and then the cut needs to be made deeper. The narrow strip can be used to "measure" the length of bezel wire needed around the perimeter of a stone.

Step 3

Since 12mm cabochons were not available, 12mm malachite puffed coins make excellent stand-ins for a pair of earrings being made.

Wrap a piece of tape around the outer edge of the stone (either cabochon or bead), overlapping slightly.

Cut the tape several millimeters too long. Folding the tape back and creasing at that point will give you a line to cut on.

Secure the tape to the bezel strip. Cut the bezel wire using the tape length as a guide. An alternative would be to use post-it note strips instead of tape around stones.

Wrap a piece of tape around the outer edge of the stone (either cabochon or bead), overlapping slightly.

Cut the tape several millimeters too long. Folding the tape back and creasing at that point will give you a line to cut on.

Secure the tape to the bezel strip. Cut the bezel wire using the tape length as a guide. An alternative would be to use post-it note strips instead of tape around stones.

Step 4

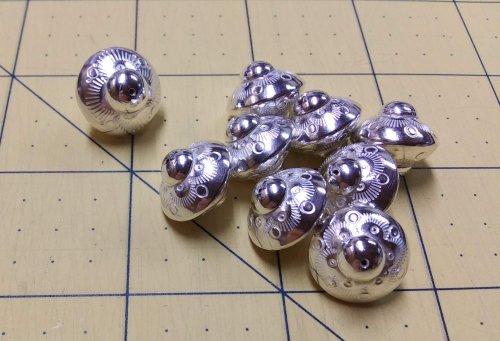

Bezel wire strips have a "front" and a "back" side. In other words, one side looks different than the other.

When the bezel wire is cut, the cutting blade pressed into the metal, pushing a very small amount of metal to the "back" side of the strip, creating a faint ridge. It was not intentional to photograph a face, but it makes it easy to point out that the top "lip" is the "back" side of the bezel strip and the bottom lip is the "front" side.

It is up to you which side you want to face out, but it is something to be aware of if you are making matching items, like earrings.

When the bezel wire is cut, the cutting blade pressed into the metal, pushing a very small amount of metal to the "back" side of the strip, creating a faint ridge. It was not intentional to photograph a face, but it makes it easy to point out that the top "lip" is the "back" side of the bezel strip and the bottom lip is the "front" side.

It is up to you which side you want to face out, but it is something to be aware of if you are making matching items, like earrings.

Step 5

Since plain bezel wire is much less expensive than decorative bezel wires, I am not worried about cutting a slightly longer piece than needed. This gives me room to square the ends up, and squared ends make for a more perfect join.

This method works well when making multiples of the same thing. Even though I ordered several different calibrated stone cabochons, they were not all the same size or height, just close. It was easiest to measure and make all the bezels fit the largest cabochon.

Once the EXACT length of bezel wire needed for the largest cabochon was determined, a piece of tape that length was secured to my work surface and all the other strips were filed to the same length.

This method works well when making multiples of the same thing. Even though I ordered several different calibrated stone cabochons, they were not all the same size or height, just close. It was easiest to measure and make all the bezels fit the largest cabochon.

Once the EXACT length of bezel wire needed for the largest cabochon was determined, a piece of tape that length was secured to my work surface and all the other strips were filed to the same length.

Step 6

If making multiples such as earrings, it is advisable to mark the back of the stones. If the stones are dark colored, or you don't want to mark them, use a bit of painter's tape to label the back of the stones.

Step 7

Once the bezel wire is cut, square up one end. A miter jig and vise is a perfect tool for this. Place the bezel wire flush against the flat fence (looks like a tooth) and tighten the screws down. File the little bit of bezel wire sticking out of the miter jig flush with the surface of the jig-first photo. Label the squared end with a Sharpie-second photo.

Pro Tip: Before putting the bezel wire coil back in the package, square up the leading end. That way, you are ready to quickly start the next project-third photo.

Step 8

Form the bezel wire around the cabochon. If the cabochon is not round, the seam should be placed in the center of the longest straight side, if possible-See the third photo in Step 3. Overlap the bezel wire around the stone. Use an ultra fine point retractable Sharpie to mark the overlap on the bezel wire-first photo. Remove excess bezel wire in the same manner as Step 7 until the ends meet when wrapped around the cabochon, making for a snug fit-second photo.

Step 9

If a higher profile is desired for a thinner stone, as with the amazonite in Step 1, old hotel room keys can be cut to fit inside the bezel.

If a stone is very thin and fragile, or the jewelry item being made can easily get knocked, like a bracelet, cuff, or ring, the shims should entire bottom of the bezel to protect the stone from breaking.

Whatever is used, it should be a permanent solution, not something that can degrade over time. If the lower profile of the stone is desired, the bezel should be cut down before soldering the ends together.

If a stone is very thin and fragile, or the jewelry item being made can easily get knocked, like a bracelet, cuff, or ring, the shims should entire bottom of the bezel to protect the stone from breaking.

Whatever is used, it should be a permanent solution, not something that can degrade over time. If the lower profile of the stone is desired, the bezel should be cut down before soldering the ends together.

Step 10

How bezel ends are cut and soldered together is personal preference. This is just the way I do it. It is very important to match up both ends of the bezel wire so no light shows through the seam.

Place the bezel on end with the seam facing down and the bezel bottom facing away from you on a soldering surface-here a hard solderite board. Since solder will not show on the inside of the bezel and I don't like to clean up solder on the outside, I place a small amount of hard paste solder along the inside seam-first photo.

What torch to use: The smaller Blazer style torches are fine for smaller bezels. With larger or thicker bezels, more heat is needed so move up to a Handy Flame Butane Torch Head on a butane canister. No matter which is used, be careful to not melt the bezel. If the metal starts to become shiny, you have heated it too much and it is about to melt. Immediately pull the flame away.

Heat around the entire bezel until the solder flows-second photo. Immediately tip the bezel over with a solder pick and heat the seam outside the bezel, pulling the solder though to the outside of the seam-third photo. This should take less than a second. Because the bezel bottom was facing away from you, when the bezel cools in a few minutes, which side you chose originally as the bottom can again be marked

Place the bezel on end with the seam facing down and the bezel bottom facing away from you on a soldering surface-here a hard solderite board. Since solder will not show on the inside of the bezel and I don't like to clean up solder on the outside, I place a small amount of hard paste solder along the inside seam-first photo.

What torch to use: The smaller Blazer style torches are fine for smaller bezels. With larger or thicker bezels, more heat is needed so move up to a Handy Flame Butane Torch Head on a butane canister. No matter which is used, be careful to not melt the bezel. If the metal starts to become shiny, you have heated it too much and it is about to melt. Immediately pull the flame away.

Heat around the entire bezel until the solder flows-second photo. Immediately tip the bezel over with a solder pick and heat the seam outside the bezel, pulling the solder though to the outside of the seam-third photo. This should take less than a second. Because the bezel bottom was facing away from you, when the bezel cools in a few minutes, which side you chose originally as the bottom can again be marked

Step 11

On a bench block, reshape the bezel around the cabochon. Half a clothespin works very well to slide around the bezel without pushing the top edge in.

Step 12

Use a Sharpie to cover the bottom of the bezel-first photo. I happen to like red because it is very visible in areas needing more sanding during the process.

Place 400 grit sandpaper on a bench block. Place the bezel bottom side down on the sandpaper. Cover the bezel with your fingers. Run the bezel across the sandpaper in a figure 8 motion, turning the bezel several times during the process so one side is not sanded more than another, until the Sharpie has been removed from the bottom edge of the bezel-second photo. It will now be flat. Reshape the bezel if needed.

Place 400 grit sandpaper on a bench block. Place the bezel bottom side down on the sandpaper. Cover the bezel with your fingers. Run the bezel across the sandpaper in a figure 8 motion, turning the bezel several times during the process so one side is not sanded more than another, until the Sharpie has been removed from the bottom edge of the bezel-second photo. It will now be flat. Reshape the bezel if needed.

Step 13

It has become habit for me to use painter's tape on the back of cabochons. For all stones that are not round, once the bezels are reshaped I mark an arrow on painters tape on the back of the stone pointing to the bezel seam so it will be easy to set the stone in the bezel later.

Step 14

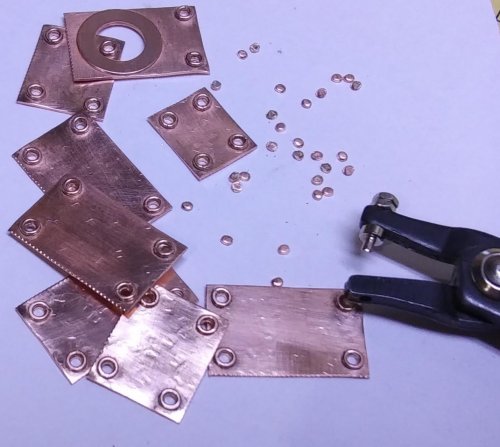

Decide on the size of backplate needed for the project and cut it out-first photo and second photos. Do you want to see the stone from the back? Now is the time to cut the hole/design-second and third photos.

Flatten the backplate on a bench block using a rubber/nylon or rawhide mallet.

Clean the backplate. When metals are dirty, solder joins can fail. This does not often happen, but why chance it. Sanding with a fine sanding pad and cleaning off with an alcohol soaked pad is usually all that is needed to clean the backplate to ready it for a good solder join-fourth photo.

Flatten the backplate on a bench block using a rubber/nylon or rawhide mallet.

Clean the backplate. When metals are dirty, solder joins can fail. This does not often happen, but why chance it. Sanding with a fine sanding pad and cleaning off with an alcohol soaked pad is usually all that is needed to clean the backplate to ready it for a good solder join-fourth photo.

Step 15

Since hard paste solder was used to secure the bezel ends together, medium paste solder should be used. Remember, start with the solder with the highest temperature flow point and work down with each succeeding solder join.

Place medium paste solder around the bottom of the bezel, or inside at the bottom of the bezel. Since a twisted decorative wire was added to the bezel shown, placing the solder on the bottom of the bezel also secured the twisted wire to the backplate.

After placing the bezel (and other decorative elements) in place on the backplate, place the unit on a raised wire screen so heat can get under it to help the solder flow-third photo.

The backplate is the largest element, with the twisted wire coming in second. Concentrating the heat around the bezel will result in the bezel melting. Always heat up the element/elements with the most mass before ever going to anything smaller or thinner.

Heat around the outside of the backplate and occasionally over the bezel and decorative elements until the solder flows.

Place medium paste solder around the bottom of the bezel, or inside at the bottom of the bezel. Since a twisted decorative wire was added to the bezel shown, placing the solder on the bottom of the bezel also secured the twisted wire to the backplate.

After placing the bezel (and other decorative elements) in place on the backplate, place the unit on a raised wire screen so heat can get under it to help the solder flow-third photo.

The backplate is the largest element, with the twisted wire coming in second. Concentrating the heat around the bezel will result in the bezel melting. Always heat up the element/elements with the most mass before ever going to anything smaller or thinner.

Heat around the outside of the backplate and occasionally over the bezel and decorative elements until the solder flows.

Pro Tip: If a stone must be raised because it is too thin, metal pieces that raise it to the desired height can be soldered onto the backplate inside the bezel. Just make sure they do not touch the bezel wall as that can make it more difficult for the solder to flow-second and third photos.

Step 16

Pickle, rinse, and dry the piece.

Step 17

When making multiples, scratching the number corresponding to the bead/cabochon number in the bottom of the bezel is helpful.

Step 18

Flatten the top edge of the bezel in the same manner as Step 12.

Step 19

Trim, file, and refine the edge of the bezel. It can be helpful to draw a cutting line with an ultra fine point retractable Sharpie marker.

This bezel was used in the cuff shown. It was soldered to a brass backplate using easy paste solder. Cutting the holes in the backplates was a cost saving measure because I wanted the discs for another project. The finished brass section was riveted in place on a cuff base.

This bezel was used in the cuff shown. It was soldered to a brass backplate using easy paste solder. Cutting the holes in the backplates was a cost saving measure because I wanted the discs for another project. The finished brass section was riveted in place on a cuff base.

Step 20:

Setting the stone

If using shims that are not attached to the backplate, place them in the bottom of the bezel. Place the cabochon on top and push down to seat the cabochon inside the bezel.

Step 21

If a metal bezel pusher/roller/burnisher slips, it can scratch the metal and/or cabochon. Wood does not scratch in that manner. Photos below show a favorite bezel pusher of mine-half a wooden clothespin-in use

Step 22

Carefully use your desired tool to push the bezel in over the cabochon. The following photos show a bezel roller in action.

If using a bezel roller, make sure that the rounded edge is facing down if you have not altered the roller to make both top and bottom edges smooth and round. The square edge side can definitely scratch the surface of the stone/cabochon but the rounded edge poses less of a risk. If concerned, covering the stone/cabochon with painter's tape can help with that worry, but it is not fool-proof. Whatever tool is used, the steps are the same. Just be slow and methodical. That way you will have less of a chance to scratching the surface of the stone.

Think of the bezel as a clock. Starting at 6 o'clock, gently push the top of the bezel wire toward the cabochon, rocking the bezel roller back and forth to push about ¼" of the bezel in. Move to 12 o'clock and do the same thing to the bezel there. Here, it would be difficult to get into that small space. The pointed wooden dowel seen in Step 21 was used there.

If using a bezel roller, make sure that the rounded edge is facing down if you have not altered the roller to make both top and bottom edges smooth and round. The square edge side can definitely scratch the surface of the stone/cabochon but the rounded edge poses less of a risk. If concerned, covering the stone/cabochon with painter's tape can help with that worry, but it is not fool-proof. Whatever tool is used, the steps are the same. Just be slow and methodical. That way you will have less of a chance to scratching the surface of the stone.

Think of the bezel as a clock. Starting at 6 o'clock, gently push the top of the bezel wire toward the cabochon, rocking the bezel roller back and forth to push about ¼" of the bezel in. Move to 12 o'clock and do the same thing to the bezel there. Here, it would be difficult to get into that small space. The pointed wooden dowel seen in Step 21 was used there.

Step 23

Just as in Step 22, work opposite sides of the bezel. Starting at 9 o'clock, gently push the top of the bezel wire toward the cabochon, rocking the bezel roller back and forth to push about ¼" of the bezel in. Do the same thing at 3 o'clock.

Step 24

Four quadrants have been created. Starting in the center of one quadrant, gently push the top of the bezel wire toward the cabochon, rocking the bezel roller back and forth to push about ¼" of the bezel in. Because the opposite side is under the leaf, the tip of a stiff narrow short blade knife was used to push the bezel down.

Step 25

Repeat Step 24 in the other quadrants.

Step 26

Use the bezel roller to continue to push the bezel wire in until no more gaps are left.

Step 27

A bezel burnisher can be used to smooth and shine the top edge of the bezel after it has been pushed in. Shown is the one I use, but because there are many different types and sizes of burnishers as well as ways to hold them, it is a good idea to watch a few videos featuring the type of burnisher you may have.

Step 28

Basic bezel wire does not have to be used just as bezels for stones. Try your hand at weaving some pieces together and then texturing the piece. There are so many designs this could be used in!

Beaded Briolette Pendant

Beaded Briolette Pendant Snail Trail Spiral Earrings

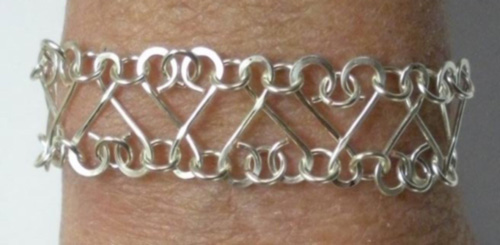

Snail Trail Spiral Earrings Heart Link Bracelet and Earrings

Heart Link Bracelet and Earrings Crazy Hoop Earrings

Crazy Hoop Earrings Double Delight Jade Bracelet

Double Delight Jade Bracelet Swagged Pearl Pendant

Swagged Pearl Pendant Heart Earrings with Drops

Heart Earrings with Drops Scarab Bracelet

Scarab Bracelet Birthstone Heart Pendant

Birthstone Heart Pendant Pearl of the Sea Woven Pendant

Pearl of the Sea Woven Pendant Bead Charm

Bead Charm Coiled Rosette Link

Coiled Rosette Link Wire Jewelry Component and Swan Hook

Wire Jewelry Component and Swan Hook Leaf Bail

Leaf Bail  Component Templates with Heart Earrings and Pendant

Component Templates with Heart Earrings and Pendant Ring Pendant

Ring Pendant Calla Lily Earrings

Calla Lily Earrings Birdhouse Pendant

Birdhouse Pendant Clamshell Earrings and Pendant

Clamshell Earrings and Pendant Bracelet Component

Bracelet Component Teardrop Earrings and Pendant

Teardrop Earrings and Pendant Tab Style Pendant

Tab Style Pendant Coiled End Caps

Coiled End Caps Freeform Pendant

Freeform Pendant French Hook Ear Wires

French Hook Ear Wires Necklace Component

Necklace Component Triangle Shield Earrings, Pendant and Bail

Triangle Shield Earrings, Pendant and Bail How to Make a Wire Coil and Bead

How to Make a Wire Coil and Bead Egyptian Coil Bracelet

Egyptian Coil Bracelet Focal Bead Egyptian Coiled Bracelet

Focal Bead Egyptian Coiled Bracelet Sweetheart Round Cabochon Pendant

Sweetheart Round Cabochon Pendant Making Cobblestone Cabochons

Making Cobblestone Cabochons Cupcake Wrapper Earrings

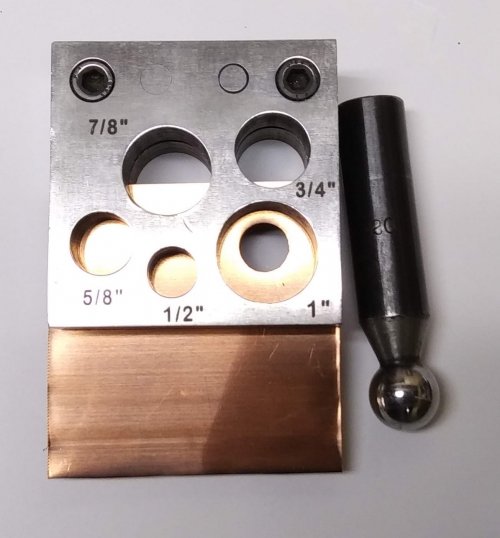

Cupcake Wrapper Earrings How to Make Metal Washers

How to Make Metal Washers Baseball Skin Keychain

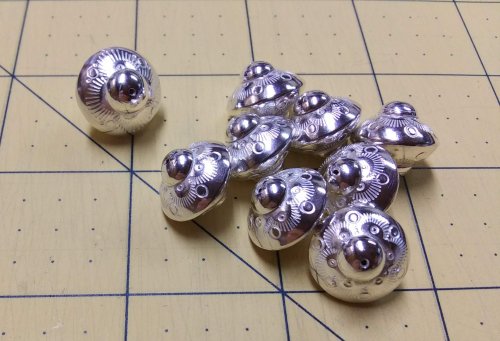

Baseball Skin Keychain Pat's Silver Domed Earrings

Pat's Silver Domed Earrings Blaze Your Own Path Pendant

Blaze Your Own Path Pendant Semi Snap-on Bail

Semi Snap-on Bail Interlocking Faux Twist Wire Bracelet

Interlocking Faux Twist Wire Bracelet Fold Formed Cuff With Faux Roman Glass or Coin Cabochon

Fold Formed Cuff With Faux Roman Glass or Coin Cabochon Steampunk Style Leaf Earrings

Steampunk Style Leaf Earrings Stamped Saucer Beads

Stamped Saucer Beads Kat's Wire Hoop Earrings

Kat's Wire Hoop Earrings Simple Bail on a Coin Pendant

Simple Bail on a Coin Pendant Wire Bangles

Wire Bangles Rolling Mill - or not - Cuff Bracelet

Rolling Mill - or not - Cuff Bracelet Jen's Chain

Jen's Chain Making Neckwires

Making Neckwires Silver Scrap Wire Focals to Embellish

Silver Scrap Wire Focals to Embellish Splash Ring

Splash Ring Cobblestone Cab Earrings

Cobblestone Cab Earrings Multi Gemstone Necklace

Multi Gemstone Necklace Southwest Style Pendant

Southwest Style Pendant Bezels Using Square Wire

Bezels Using Square Wire Mixed Metal Sampler Bracelet 1

Mixed Metal Sampler Bracelet 1 Mixed Metal Sampler Bracelet 2

Mixed Metal Sampler Bracelet 2 Mixed Metal Sampler Bracelet 3

Mixed Metal Sampler Bracelet 3 Mixed Metal Sampler Bracelet 4 - Words Matter

Mixed Metal Sampler Bracelet 4 - Words Matter Mixed Metal Sampler Bracelet 5 - River Walk

Mixed Metal Sampler Bracelet 5 - River Walk  Mixed Metal Sampler Bracelet 6 - A Little Bling

Mixed Metal Sampler Bracelet 6 - A Little Bling Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER

Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER  Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity

Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity Mixed Metal Sampler Bracelet 8 - Fun Shapes

Mixed Metal Sampler Bracelet 8 - Fun Shapes Jump Ring Fringe Bracelet

Jump Ring Fringe Bracelet Easy Artisan Earrings

Easy Artisan Earrings Making Chain with Wubbers and Wire

Making Chain with Wubbers and Wire Heirloom Buttons and Beads Bracelet

Heirloom Buttons and Beads Bracelet  Tiny Silver Charms part 1

Tiny Silver Charms part 1 Argentium Silver Scrap Chain

Argentium Silver Scrap Chain Sterling Lake Stone Pendant with Twisted Wire

Sterling Lake Stone Pendant with Twisted Wire Smashing Drop Earrings

Smashing Drop Earrings Argentium Silver Scrap Nugget Cuff

Argentium Silver Scrap Nugget Cuff Finish Them Your Way Earrings

Finish Them Your Way Earrings Paddle Fringe Earrings

Paddle Fringe Earrings Seed Bead Earrings

Seed Bead Earrings Bracelet Links 1, 2,3

Bracelet Links 1, 2,3 Stamped Saucer Beads

Stamped Saucer Beads Chaos Scrap Wrap Jewelry

Chaos Scrap Wrap Jewelry Maple Leaf Earrings

Maple Leaf Earrings Child's Bracelet That Grows with Them

Child's Bracelet That Grows with Them Mike's Surpirise Claire's Ripple Pendant

Mike's Surpirise Claire's Ripple Pendant Angel Ornament

Angel Ornament  Diamonds, Emeralds, and Sapphires, Oh My.

Diamonds, Emeralds, and Sapphires, Oh My.  Treasure Bezel Cups

Treasure Bezel Cups Three Leaves Earrings

Three Leaves Earrings Silver and Gold Earrings

Silver and Gold Earrings Make a Hidden Bail

Make a Hidden Bail Wire Links 4, 5, 6

Wire Links 4, 5, 6 Wire Links 7, 8, 9, and 10

Wire Links 7, 8, 9, and 10 Double Loop Ear Wires

Double Loop Ear Wires Balled and Paddled Head Pins

Balled and Paddled Head Pins Textured Stacked Rings

Textured Stacked Rings Cord and Bead Earrings

Cord and Bead Earrings Bali Style Adjustable Closures

Bali Style Adjustable Closures Organic Fused Silver Dust Earrings

Organic Fused Silver Dust Earrings Mobius Rings

Mobius Rings Dainty Bead and Wire Bangle with Hook Closure

Dainty Bead and Wire Bangle with Hook Closure Seed Bead and Nugget Necklace

Seed Bead and Nugget Necklace Love Locks Heart Charm

Love Locks Heart Charm Traditional Southwest Style Hook Closures

Traditional Southwest Style Hook Closures  Negative Space Earrings

Negative Space Earrings Jumbled Lacy Chain

Jumbled Lacy Chain Easy Beaded Post Hoop Earrings

Easy Beaded Post Hoop Earrings Rustic Silver Links

Rustic Silver Links Make a Soldered Paperclip Chain

Make a Soldered Paperclip Chain Make a Fused Paperclip Chain

Make a Fused Paperclip Chain Make Woven Metal Strips to Use in Your Designs

Make Woven Metal Strips to Use in Your Designs Leaf Wrap Metal Rings version 1

Leaf Wrap Metal Rings version 1 Leaf Wrap Metal Rings version 2

Leaf Wrap Metal Rings version 2 Snowflake Ornaments

Snowflake Ornaments Mitten Ornament

Mitten Ornament Gnome Ornaments

Gnome Ornaments A Partridge in a Pear Tree Earrings

A Partridge in a Pear Tree Earrings Two Turtle Doves Earrings

Two Turtle Doves Earrings Three French Hens Earrings

Three French Hens Earrings Four Calling Birds Earrings

Four Calling Birds Earrings Five Golden Rings Earrings

Five Golden Rings Earrings Six Geese a Layin' Earrings

Six Geese a Layin' Earrings Seven Swans a Swimming Earrings

Seven Swans a Swimming Earrings Eight Maids a Milking earrings

Eight Maids a Milking earrings Nine Ladies Dancing Earrings

Nine Ladies Dancing Earrings Ten Lords a Leaping Earrings

Ten Lords a Leaping Earrings Eleven Pipers Piping Earrings

Eleven Pipers Piping Earrings Twelve Drummers Drumming Earrings

Twelve Drummers Drumming Earrings Make Your Own Bracelet Button Clasps

Make Your Own Bracelet Button Clasps Little Saucer Bells

Little Saucer Bells Doodads - Fun Findings

Doodads - Fun Findings No Measure Hearts, Any Size, Any Gauge

No Measure Hearts, Any Size, Any Gauge  Cascading Drops Earrings

Cascading Drops Earrings WIre Basics - Spiral Charms

WIre Basics - Spiral Charms Wire Basics - Wrapped Loops and Links

Wire Basics - Wrapped Loops and Links Wire Basics - Simple Swan Hook

Wire Basics - Simple Swan Hook Wire Crocheted Necklace

Wire Crocheted Necklace Wire Basics - Wire Garage Door Spring Link

Wire Basics - Wire Garage Door Spring Link Easy Post Hoop Earrings

Easy Post Hoop Earrings Double Wrap Wire Bangle Bracelet

Double Wrap Wire Bangle Bracelet Organic Wire Pendant

Organic Wire Pendant Coiled, Beaded Slide

Coiled, Beaded Slide Cone and Chain Earrings

Cone and Chain Earrings Embellished Sterling Cones

Embellished Sterling Cones Classic Wire Wrap Bezelled Pendant

Classic Wire Wrap Bezelled Pendant Wire Wrap a Coin

Wire Wrap a Coin Viking Knit

Viking Knit Viking Knit Bracelet

Viking Knit Bracelet Coiled Wire End Caps

Coiled Wire End Caps Bead-Wrapped Hoop Earrings

Bead-Wrapped Hoop Earrings Copper Feather Earrings

Copper Feather Earrings Soldering a Dome to a Backplate

Soldering a Dome to a Backplate  Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop Make Basic Wire Shapes for Jewelry

Make Basic Wire Shapes for Jewelry Make Simple Wire Slide Bails

Make Simple Wire Slide Bails Coiled Bead and Twisted Wire Bracelet

Coiled Bead and Twisted Wire Bracelet Wire Triangle Link

Wire Triangle Link Bali Style Focal Toggle

Bali Style Focal Toggle Silver Nuggets

Silver Nuggets Fun Shapes Fish Hook Earrings

Fun Shapes Fish Hook Earrings After the Rain Bracelets

After the Rain Bracelets Dangling Drop Earrings

Dangling Drop Earrings Dangling Chain Sticks

Dangling Chain Sticks Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop  Tropical Leaf Earrings

Tropical Leaf Earrings Dog Tag Style Necklace

Dog Tag Style Necklace Lacy Washers

Lacy Washers 8-Strand Kumihimo

8-Strand Kumihimo Closed Loop Ear Wires

Closed Loop Ear Wires Simple Strip Bails from Scratch

Simple Strip Bails from Scratch Anti-tarnish Silver Cloth Bags

Anti-tarnish Silver Cloth Bags Cotter Pin Style Bail

Cotter Pin Style Bail Holiday Woodland Fairy Ornament

Holiday Woodland Fairy Ornament Happy Holly Days Wreath Ornament

Happy Holly Days Wreath Ornament Happy Holly Days Leaves and Berries

Happy Holly Days Leaves and Berries Happy Holly Days Bells Ornament

Happy Holly Days Bells Ornament  Art Deco Wire Wrapped Pendant

Art Deco Wire Wrapped Pendant Twisted Wire Jump Rings

Twisted Wire Jump Rings Two-tone Beaded Bangle

Two-tone Beaded Bangle Sweetheart Pendant

Sweetheart Pendant Waves on the Beach Earrings

Waves on the Beach Earrings Any Size Wire Hearts - Any Size, Any Gauge

Any Size Wire Hearts - Any Size, Any Gauge Just in Case Heart Pendant

Just in Case Heart Pendant Small Flower Embellishment

Small Flower Embellishment Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves Spinner Fidget Bangles

Spinner Fidget Bangles Small Flower Bud Embellishment

Small Flower Bud Embellishment Three Petal Bud and Layered Embellishment

Three Petal Bud and Layered Embellishment Creating a Flower Stem

Creating a Flower Stem Stamped Tube Beads

Stamped Tube Beads Water Cast Scrap Cross

Water Cast Scrap Cross Sugared Grapes Pendant

Sugared Grapes Pendant Tourist Rock Cuff Bracelet

Tourist Rock Cuff Bracelet Gemstone Chains Reimagined

Gemstone Chains Reimagined Checkerboard Faceted Earrings

Checkerboard Faceted Earrings Foxtail Chain aka Loop-in-Loop

Foxtail Chain aka Loop-in-Loop Handmade Chunky Chain

Handmade Chunky Chain Capture a Summer Memory

Capture a Summer Memory Stone Key Fob

Stone Key Fob Sprinkles Link

Sprinkles Link Ball Chain Embellishments

Ball Chain Embellishments Handmade Ornament Hooks

Handmade Ornament Hooks