Well, That Didn't Work, Now What

I LOVE organic style jewelry-anything that looks like it was dug up at an ancient archeological site.

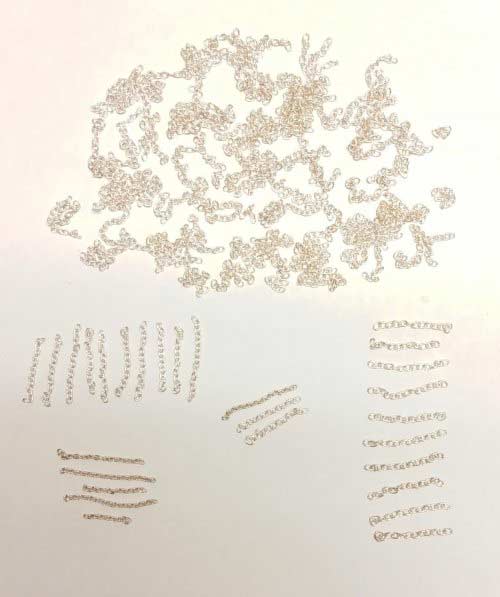

An idea for a new "old" style of link to embellish popped into my mind, so of course, I ran with it, cut a bunch of wire, and made it all into rings instead of making just one to see if it would work.

All the rings were then made into ovals and tightly twisted to look like rope with small loops on the end. Not one of the twisted links looked like I envisioned so they sat in a box on my work desk for several months because I could not bring myself to melt them down.

I thought maybe I could anneal them, untwist them, and round them on a hoop mandrel. That didn't work out how I expected either. But I loved the organic look of the rings so they were stored until I could figure out what to do with them. Fast forward two years and I finally decided how to use them.

An idea for a new "old" style of link to embellish popped into my mind, so of course, I ran with it, cut a bunch of wire, and made it all into rings instead of making just one to see if it would work.

All the rings were then made into ovals and tightly twisted to look like rope with small loops on the end. Not one of the twisted links looked like I envisioned so they sat in a box on my work desk for several months because I could not bring myself to melt them down.

I thought maybe I could anneal them, untwist them, and round them on a hoop mandrel. That didn't work out how I expected either. But I loved the organic look of the rings so they were stored until I could figure out what to do with them. Fast forward two years and I finally decided how to use them.

Read through the tutorial before starting the project. Follow all safety precautions pertaining to the tools and supplies being used and the space you are working in.

There are two ways to make the outer ripple rings.

Option A: Make a coil on the middle step of a large Wrap "N" Tap pliers using 16-gauge round wire. Cut rings from the coil making sure to flush cut both ends.

Option B: Flush cut both ends of a straight piece of 16-gauge round wire, making the wire 2-9/16" long

There are two ways to make the outer ripple rings.

Option A: Make a coil on the middle step of a large Wrap "N" Tap pliers using 16-gauge round wire. Cut rings from the coil making sure to flush cut both ends.

Option B: Flush cut both ends of a straight piece of 16-gauge round wire, making the wire 2-9/16" long

Close the rings so the seam is so tight no light can be seen through it and the ends are perfectly even. The same holds true when forming the straight wire lengths into ovals.

Place the closed rings and ovals on a soldering surface.

I usually use Argentium wire. When making large rings like this I like to fuse the ends together. This is one of the rare times I will use solder. It does not make any difference if paste, wire, or sheet solder is used.

If the rings/ovals are Argentiium, use medium solder. If the rings/ovals are sterling, use hard or medium solder.

Place the solder under the seam and heat until the solder flows up through the seam.

Place the closed rings and ovals on a soldering surface.

I usually use Argentium wire. When making large rings like this I like to fuse the ends together. This is one of the rare times I will use solder. It does not make any difference if paste, wire, or sheet solder is used.

If the rings/ovals are Argentiium, use medium solder. If the rings/ovals are sterling, use hard or medium solder.

Place the solder under the seam and heat until the solder flows up through the seam.

Pro Tip: The oval shapes will be easier to work with if made a bit more round by sliding them onto a hoop mandrel and pushing them down the cone shape with your fingers. There is no need to hammer them.

Pickle, rinse, and dry the rings/ovals.

Making sure that the soldered seams are at one end of the ovals, stretch all the rings into ovals using the small Wrap "N" Tap pliers as shown.

Squish (technical term) the centers of the wire ovals together using soft jaw pliers.

Grasp the ends of a wire oval with soft jaw pliers. Twist the oval tightly to resemble a rope twist.

The amount of twist seen in the photos was not enough. One or two more twists should have been made for a better ripple effect on the finished ring.

The amount of twist seen in the photos was not enough. One or two more twists should have been made for a better ripple effect on the finished ring.

Place the twisted rings on a soldering surface and anneal them. Make sure the rings do not get so hot that the twists will fuse together.

Grasp the ends of a twisted wire with soft jaw pliers. Untwist the wire. The untwisted rings will not be round.

Slide an untwisted ring on a hoop mandrel. Use a rubber, nylon, or rawhide mallet to reshape it into a round while still keeping the ripple from the twist. If needed, each ring can be very lightly flattened on a bench block.

There are two ways to make the inner rings.

Option A: Make a coil on the smallest step of a large Wrap "N" Tap pliers using 18-gauge round wire. Cut rings from the coil making sure to flush cut both ends.

Option B: Flush cut both ends of a straight piece of 18-gauge round wire, making the wire 1-15/16" long.

Follow Steps 2, and 3 to complete making the rings. If straight wire was used, round them on a hoop mandrel as in Step 9.

Option A: Make a coil on the smallest step of a large Wrap "N" Tap pliers using 18-gauge round wire. Cut rings from the coil making sure to flush cut both ends.

Option B: Flush cut both ends of a straight piece of 18-gauge round wire, making the wire 1-15/16" long.

Follow Steps 2, and 3 to complete making the rings. If straight wire was used, round them on a hoop mandrel as in Step 9.

Ball a 1¾" piece of 18-gauge round wire for each earring focal being made. Clean the soldering surface residue from the back of each ball before continuing.

Use a flat faced hammer to flatten all the balls so they are similar in size. Hammer the sides of the flattened balls with a domed faced hammer, creating a more "nugget" or "faceted" look to the top of each flattened ball.

Close the 18 gauge 3.5mm ID jump rings. Set all the pieces together on a soldering surface.

The seam in the jump ring should touch the outer ripple ring. If desired, change the placement of the parts.

Center the inner ring at the bottom of the ripple ring. Center a flattened ball at the bottom of the inner ring.

The seam in the jump ring should touch the outer ripple ring. If desired, change the placement of the parts.

Center the inner ring at the bottom of the ripple ring. Center a flattened ball at the bottom of the inner ring.

An overabundance of medium paste solder was used here to connect the parts. The reason for this is that the ripple ring may not have much contact area with the inner ring because of the ripples.

While removing the excess paste solder with a Q-tip or a tissue, much of the excess paste solder is pressed into the seams between the rings and flattened balls. Wherever the two rings make contact will then be soldered together.

Make sure that all the parts are pushed tightly together. Heat until the solder flows. Allow the pieces to cool naturally.

While removing the excess paste solder with a Q-tip or a tissue, much of the excess paste solder is pressed into the seams between the rings and flattened balls. Wherever the two rings make contact will then be soldered together.

Make sure that all the parts are pushed tightly together. Heat until the solder flows. Allow the pieces to cool naturally.

Check the solder joins. Re-solder if needed. Pickle, rinse, and dry the pieces.

Use sanding pads to clean and refine the solder joins.

Tumble the finished pieces for several hours to bring up a nice shine.

If a soft brushed finish is desired, place the piece on a bench block and run a soft steel brush across the surface of the piece several times.

Tumble the finished pieces for several hours to bring up a nice shine.

If a soft brushed finish is desired, place the piece on a bench block and run a soft steel brush across the surface of the piece several times.

The right earring finding plays a big role in making an organic style focal look modern. Steering clear of patina also helps because bright silver paired with a more modern earring finding will have a current vibe.

These ear wires are a more modern take on a standard French hook ear wire. Not everyone can or will wear longer earrings. If that is the case, choose the shorter version. Choose the longer version for a bit more drama.

Flush cut both ends of 20-gauge full hard round wire to make the following lengths: Shorter version-3", Longer version-4".

These ear wires are a more modern take on a standard French hook ear wire. Not everyone can or will wear longer earrings. If that is the case, choose the shorter version. Choose the longer version for a bit more drama.

Flush cut both ends of 20-gauge full hard round wire to make the following lengths: Shorter version-3", Longer version-4".

Make a loop on one end of each wire using the smallest step on a 6 step barrel plier.

Full hard wire is hard to straighten so make sure the first bend is made toward the inside curve of the wire.

Full hard wire is hard to straighten so make sure the first bend is made toward the inside curve of the wire.

Make another loop on the next step up on the 6 step barrel pliers. This loop should be bent towards the outside curve of the wire.

Use a cup bur and sanding pads to remove sharp edges and smooth the cut end of the wire that will enter the ear piercing.

Place an ear wire on a ruler as shown. Use an ultra fine point retractable Sharpie to mark the shorter ear wire at 1" and the longer ear wire at 1-3/8".

Center the mark between the jaws of the pliers. Use fingers to push the wires straight down on either side of the plier jaws.

The 6mm side of the Wubbers Parallel Round Pliers with 6mm and 4mm jaws makes it easy to bend two ear wires at the same time.

The curve will be EXACTLY in the same place on each one!

Step 4 on the 6 step barrel pliers will work to bend one ear wire at a time. There is a 6mm mark on the larger jaw of Acculoop Precision Round Nose Pliers to make it easy to form the same curve every time.

The 6mm side of the Wubbers Parallel Round Pliers with 6mm and 4mm jaws makes it easy to bend two ear wires at the same time.

The curve will be EXACTLY in the same place on each one!

Step 4 on the 6 step barrel pliers will work to bend one ear wire at a time. There is a 6mm mark on the larger jaw of Acculoop Precision Round Nose Pliers to make it easy to form the same curve every time.

Nylon ring bending pliers will make the same gentle curve every time at the end of each ear wire.

Now that the ear wires are done, it is decision time. To patina or not.

The ear wires can be attached and the whole earring dipped in a liver of sulfur solution. Since my personal preference is to not clean patina off ear wires, they were attached after two of the focal elements were patinated.

The ear wires can be attached and the whole earring dipped in a liver of sulfur solution. Since my personal preference is to not clean patina off ear wires, they were attached after two of the focal elements were patinated.

Attach the ear wires.

Materials

16 Gauge Round Half Hard Argentium .940 Silver Wire

H19-16H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $10.96

- Gold Club Price: $8.22

18 Gauge Round Half Hard Argentium .940 Silver Wire

H19-18H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $6.50

- Gold Club Price: $4.87

20 Gauge Round Full Hard Argentium .940 Silver Wire

H19-20FH

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $4.48

- Gold Club Price: $3.36

Tools

C.H.P Milano Italian Flush Cutter, 5 1/2 Inches

PLR-487.00

- PLR-487.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.97

- Gold Club Price: $12.73

Multi-Size Wrap 'N' Tap Pliers, Large Barrels

PLR-746.03

- PLR-746.03

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

Multi-Size Wrap 'N' Tap Pliers, Small Barrels

PLR-746.02

- PLR-746.02

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

Blazer Big Buddy Turbo Torch, Black

TRCH-8010

- TRCH-8010

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $40.00

- Gold Club Price: $30.00

Solderite Soldering Board 6 Inch by 6 Inch Soft

SOL-421.10

- SOL-421.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $14.76

- Gold Club Price: $11.07

5 1/2 Inch Nylon Flat Jaw Pliers with Replacement Jaws

G2-1

- G2-1

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $9.97

- Gold Club Price: $7.48

6 Step Barrel Plier - Pack of 1

G2-503

- G2-503

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $14.95

- Gold Club Price: $11.21

Nylon Ring Bending Pliers

PLR-841.00

- PLR-841.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $20.97

- Gold Club Price: $15.73

PROFESSIONAL QUALITY RING MANDREL 1-16

MAN-295.00

- MAN-295.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

Silver Solder Paste Hard SS75 - 1/4 T.O.

SOL-822.20

- SOL-822.20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $19.95

- Gold Club Price: $14.96

Silver Solder Paste Medium SS70 - 1/4 T.O.

SOL-822.15

- SOL-822.15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

Silver Solder Paste Soft SS65- 1/4 T.O.

SOL-822.10

- SOL-822.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.95

- Gold Club Price: $12.71

- Category: General Education

- Technique(s): General Education

What is Druzy

What is Druzy Coiled Wire Jewelry Series Part 1 - Everything New is Old

Coiled Wire Jewelry Series Part 1 - Everything New is Old Where do you create

Where do you create Soldering on Copper

Soldering on Copper Charting Your Creations

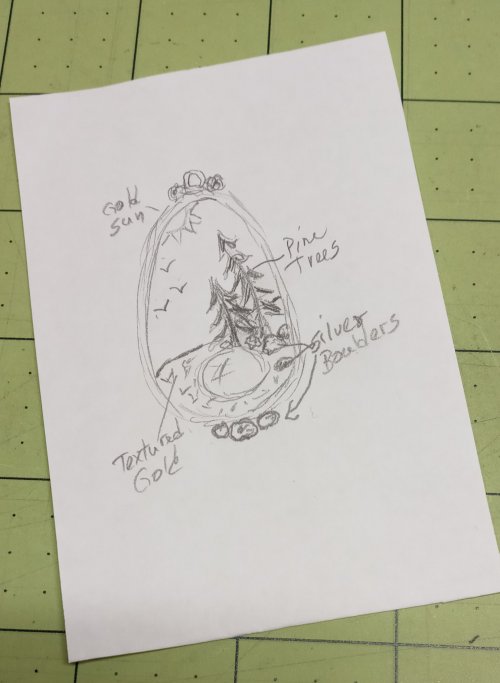

Charting Your Creations Design Process with 3 Earrings

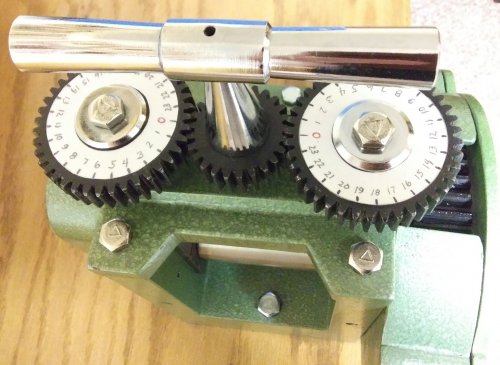

Design Process with 3 Earrings All About Rolling Mills

All About Rolling Mills How to Use Disc Cutters to Make Metal Washers

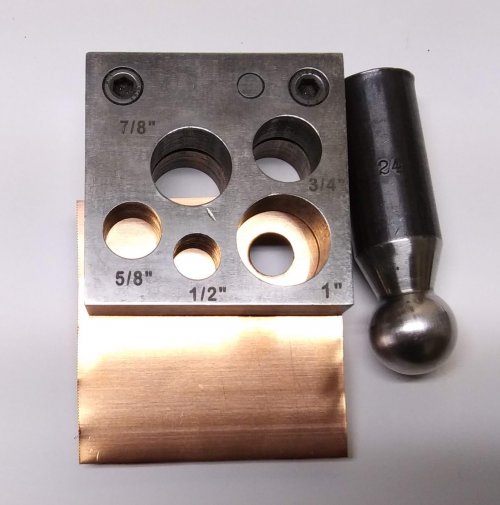

How to Use Disc Cutters to Make Metal Washers Disc Cutter Basics and How to Make Metal Washers

Disc Cutter Basics and How to Make Metal Washers I Am Not a Hoarder

I Am Not a Hoarder The Beauty of Druzy

The Beauty of Druzy Design Process with 3 Different Earrings

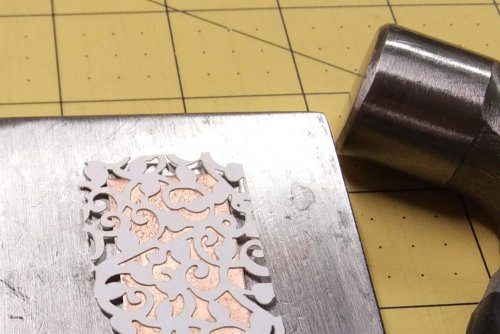

Design Process with 3 Different Earrings Think Outside the Box - Alternative Metal Texturing

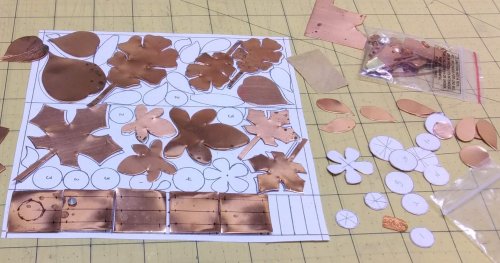

Think Outside the Box - Alternative Metal Texturing Fall Leaves for Your Designs

Fall Leaves for Your Designs Cholula "Folk Art" Charms

Cholula "Folk Art" Charms Lemons to Lemonade

Lemons to Lemonade Why You Should Take a Class

Why You Should Take a Class Bead, Shell, and Rock Cabochons

Bead, Shell, and Rock Cabochons What Tools Do I Need for Wirework and Bead Stringing - Start With The Basics

What Tools Do I Need for Wirework and Bead Stringing - Start With The Basics  Choosing Pliers

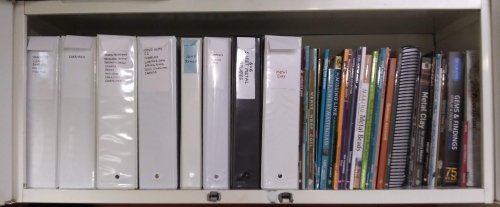

Choosing Pliers Saving, Storing, Using Tutorials

Saving, Storing, Using Tutorials Flop to Flip

Flop to Flip The Story of Turquoise

The Story of Turquoise Non Marring Tools

Non Marring Tools Using Lower Quality Beads

Using Lower Quality Beads Differences in Gold Plating

Differences in Gold Plating Inventorying Your Supplies

Inventorying Your Supplies Engineering the Multi-chain Necklace

Engineering the Multi-chain Necklace Benefits of Extender Chains

Benefits of Extender Chains My Most Often Used Embellishments

My Most Often Used Embellishments Sliding Gauges and Calipers

Sliding Gauges and Calipers Wire and Sheet Gauge Measuring Tool

Wire and Sheet Gauge Measuring Tool  Silver Plated Copper Craft Wire

Silver Plated Copper Craft Wire Jewelry from Other Cultures

Jewelry from Other Cultures Conversation Starters

Conversation Starters