Building and Using a Lightbox - Part 1

Very often we get questions about how to take great photos, so I thought I would share an older article from our blog. Some of you may have read it before, but it's such a great tip I felt it would be perfect to post again for anyone just getting started. Enjoy!

This article was originally contributed by Mike Ault and I think you will find it very useful.

This article was originally contributed by Mike Ault and I think you will find it very useful.

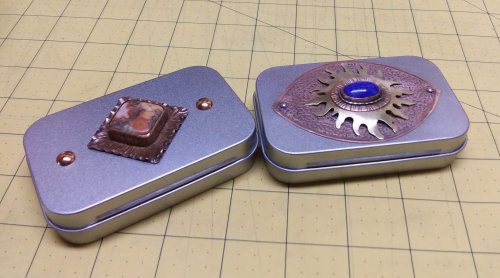

So you've designed and made an absolutely gorgeous piece of wire jewelry and want to get it on your website as soon as possible so it can be seen and generate sales. You take your camera, place the piece carefully on a neutral background, hold your breath, carefully snap a picture, only to have it turn out amateur looking at best. What can you do?

Professional product photographers use what is known as a light box to control their light and exposure for product shoots. You, as a wire jewelry maker can also take advantage of these techniques. Light boxes can be made from white milk jugs, cardboard boxes or other containers. Or, you could go out and spend anywhere from $60-1000 USD for a pre-made one. In this tip I want to show you how to make one from readily available materials that will last, be portable and produce professional looking results.

A light box is a container with light reflective sides, usually white. The floor of the light box is usually covered with either white or colored paper or fabric. Some photographers use a roll of paper so when it gets soiled, they can easily replace it.

To build your own light box all you need is time, 5 sheets of 20X30 white foam board, a marker, a ruler, a cutting surface and two 500 watt work lights. A straight edge such as a steel ruler is handy to make sure your cuts are straight.

Professional product photographers use what is known as a light box to control their light and exposure for product shoots. You, as a wire jewelry maker can also take advantage of these techniques. Light boxes can be made from white milk jugs, cardboard boxes or other containers. Or, you could go out and spend anywhere from $60-1000 USD for a pre-made one. In this tip I want to show you how to make one from readily available materials that will last, be portable and produce professional looking results.

A light box is a container with light reflective sides, usually white. The floor of the light box is usually covered with either white or colored paper or fabric. Some photographers use a roll of paper so when it gets soiled, they can easily replace it.

To build your own light box all you need is time, 5 sheets of 20X30 white foam board, a marker, a ruler, a cutting surface and two 500 watt work lights. A straight edge such as a steel ruler is handy to make sure your cuts are straight.

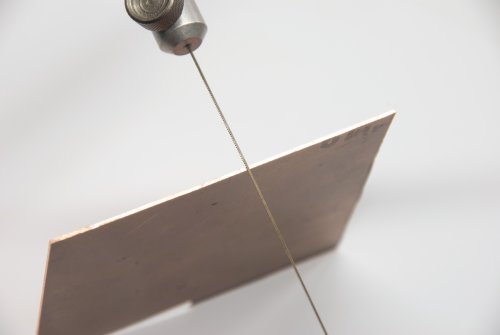

To begin, view the diagram to see how to mark your foam boards. You will need 1 each for the top, bottom, sides and back. Follow the measurements carefully, slight overcuts probably will not affect the result. Make sure you use a sharp razor or Exacto knife to do the cutting and make sure you keep fingers, arms, legs and bodies out of the way.

The slots shown only have to be wide enough to accept the edge of the foam boards. Too large and things will be shaky, too small and it will be tough getting them together.

I suggest keeping the foam cut-outs for the top's light port and shooting port as when these are not in use you will want to insert them back in place. Also keep two of the narrow cut pieces from one of the sides, you will need 2, 1 inch by 6 inch pieces later.

Once every thing is cut out, carefully piece it together. If you have measured and cut carefully it should form a hollow box about 30 inches wide and 20 deep and 20 tall. For covers for the light ports when in use (to soften the harsh light from the work lights) I use light-weight white cotton fabric attached using Velcro. Others have bought frosted or cracked glass to cover the light ports.

I suggest using a 8 x 10 piece of glass from a picture frame (just the glass is available at a hardware store in pre-cut sizes) and the 1 inch x 6 inch strips to provide a stage to set your jewelry on. This gives the picture depth.

Part 2 will be a continuation of this - discussing how to use the lightbox!

Materials

No materials listed

Tools

Displays

- Category: General Education

- Technique(s): Design, Tools, Selling, General Education

Take Photos of your Wire Jewelry using a Lightbox - Part 2

Take Photos of your Wire Jewelry using a Lightbox - Part 2 How to Edit a Jewelry Picture Using Photoshop

How to Edit a Jewelry Picture Using Photoshop