- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

Get to Know Your Hand Tools – Bench Blocks and Small Anvils – By Helen I. Driggs

by Judy Ellis, Wirejewelry.com

Wire Jewelry Tip for May 26th, 2017

Get to Know Your Hand Tools – Bench Blocks and Small Anvils

by Helen I. Driggs

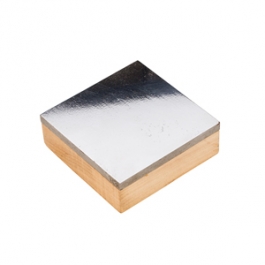

Bench Blocks and Small Anvils

A solid steel work surface is essential for many metalworking tasks like texturing, hammering, punching or stamping. Because metal is so malleable, when you apply force to it without a sturdy backing, all metal will bend, dent or stretch. Sometimes, that’s a result you want, but if you don’t, a small anvil or steel block will prevent deformation. A steel block or small anvil is one of the essential bench tools every jewelry maker should own, and you’ll use it nearly every time you work.

What to look for in a bench block

All blocks are not alike. Search for a hardened steel block to avoid damage to the steel. Soft steel will dent and those dents will transfer to the smooth surface of your metal, or worse, your smooth hammer face. Pay a little more for a polished hardened steel block from a reputable jewelry supplier. There are several standard block sizes available on the market : 3×3, 4×4 and 6×6 are most common, and there are also combo blocks that come with a rubber socket to mount the block in and deaden the noise.

Tips

1. If you are having trouble getting cleanly cut discs out of your disc cutter, put a steel block under it and then hammer on the worktop — you’ll be amazed at the difference a rigid backing makes when punching out discs or shapes.

2. Reserve one side of your block for planishing (smoothing) tasks only. I use a dot of red nail lacquer on the “do not texture” side of every steel block I own to remind me not to stamp, punch or texture there risk transferring all of those damage marks to the back side of my jewelry metal.

3. Two blocks are better than one. If you need to flatten a piece of buckled sheet metal, make a steel block “sandwich” out of two smooth blocks and put the buckled sheet in the middle. Strike the top block with a mallet to flatten the sheet.

4. To remove kinks from thick wire, roll it between two steel blocks to make it straight and to work harden the wire — also a useful technique for creating rivets.

5. To maintain a steel block or remove rust spots, use a steel bristle brush attachment in the flex shaft or a rotary tool and polish away. Then, use a few drops of light sewing machine oil to protect the newly cleaned steel.

HELEN I. DRIGGS is an experienced metalsmith, lapidary and studio jewelry instructor and has appeared in 6 instructional jewelry technique videos. Her book, The Jewelry Maker’s Field Guide was published in 2013.

Our Bench Blocks and Anvils can be found on our website WireJewelry.com!

Happy Wrapping!

![]()

Click to Receive Daily Tips by Email

0 comments