- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

Cutting Tips By Abbi Berta

by Judy Ellis, Wirejewelry.com

Wire Jewelry Tip for May 12th, 2017

Cutting Tips

by Abbi Berta

Cutting thick gauges of wire can be a tough job, especially when your cutter isn’t up to the task. Traditionally, jewelry makers have used either side cutters or jeweler’s saws to hack their way through anything thicker than 18 ga. wire. Jeweler’s saws create a straight precise cut but can be quite intimidating to a novice. Cutting wire with a side cutter is a lot quicker and easier than a saw, but almost always leaves a rough and angled cut. An unexpected tool however, a memory wire cutter, gives the best of both worlds.

You might not think the tool reserved for snapping steel memory wire would be a good choice for your precious 12 ga. Sterling Silver wire, but it is. Here are several reasons to convince you:

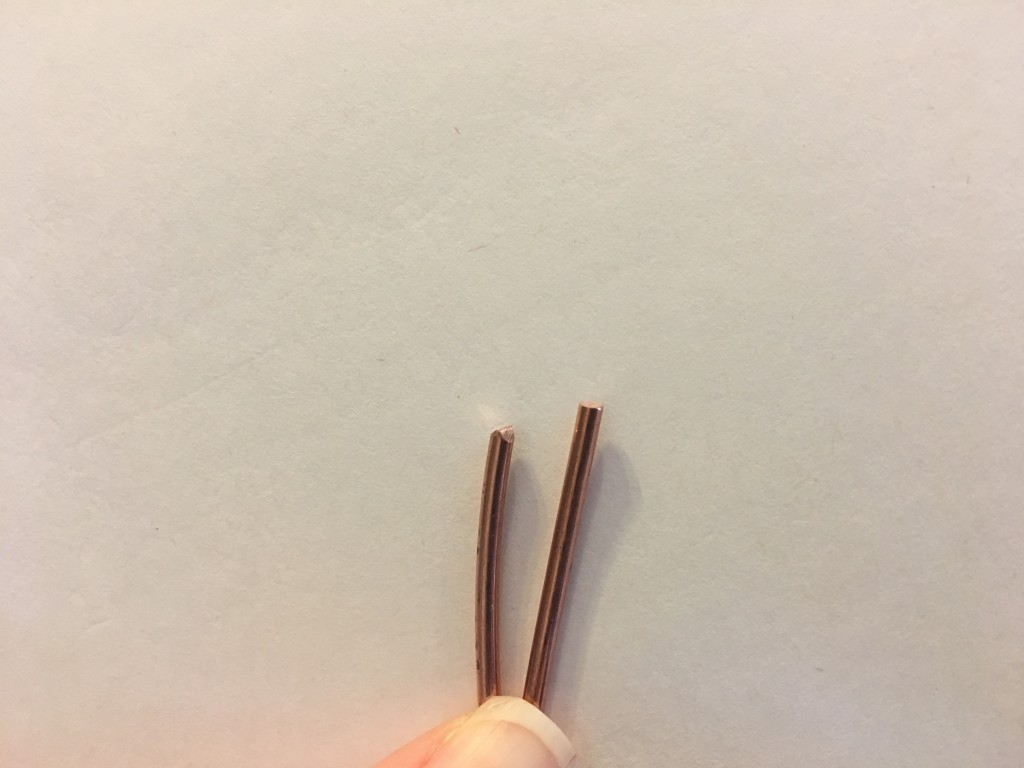

1. Most side cutters leave an angled cut on both sides of the wire (pictured top). The resulting cut from the flat side of the cutter is the “good” side and the resulting cut from the angled side of the cutter is the “bad” side. Although the “good” side is more flush than the “bad” side, it’s still not perfectly flush. Memory wire cutters create a flush cut on both sides(pictured bottom). Therefore, no filing is needed.

2. There’s no waste! When working with expensive metals, every little bit counts. The fractions of an inch that are lost with filing or back cutting add up. Because memory wire cutters leave a flush cut on both sides of the wire being cut, there’s no product lost.

3. When using a jeweler’s saw, usually other tools like a vice for example are needed to hold the wire in place as you saw through it. Unless a special attachment is used or the wire is bent, round wire often slips within the vice clamps. With a memory wire cutter, nothing additional is needed.

4. Jeweler’s saws create flush cuts on both sides of the wire but saw blades sometimes break. Memory wire cutters do not.

5. Memory wire cutters don’t make a dusty mess like saws do. Not only is this safer for your lungs, but there’s no clean up!

Hopefully these reasons have convinced you to give memory wire cutters a try on your next project.

Happy Wrapping!

![]()

Click to Receive Daily Tips by Email

Marilyn

May 12, 2017 at 8:13 am

An excellent tip! I will be getting a pair of these cutters the next trip into town – thank you!

Vicki Entrekin

May 12, 2017 at 9:26 am

Thank you! Thank you!!! This is the first time hearing this awesome tip! Thank you again!!! I love it!! ❤️❤️

Dendy2

May 12, 2017 at 10:32 am

A pair of memory wire cutters have been a part of my tool set since the very beginning of my learning how to wire wrap. I was taught at William Holland School of Lapidary Arts and continue to go back each year that I can for further instruction. Thanks for the tip for others who may not have known.

Brenda Trudell

May 12, 2017 at 11:47 pm

Excellent tip. Thank you very much. I am in a project right now and this just I need to make it more professional. Love your sites.